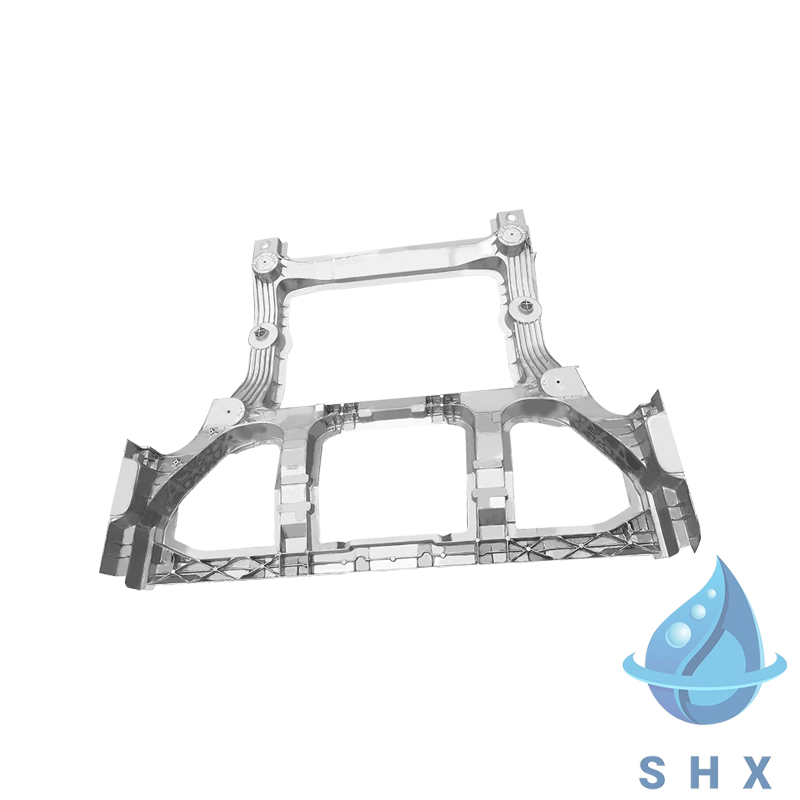

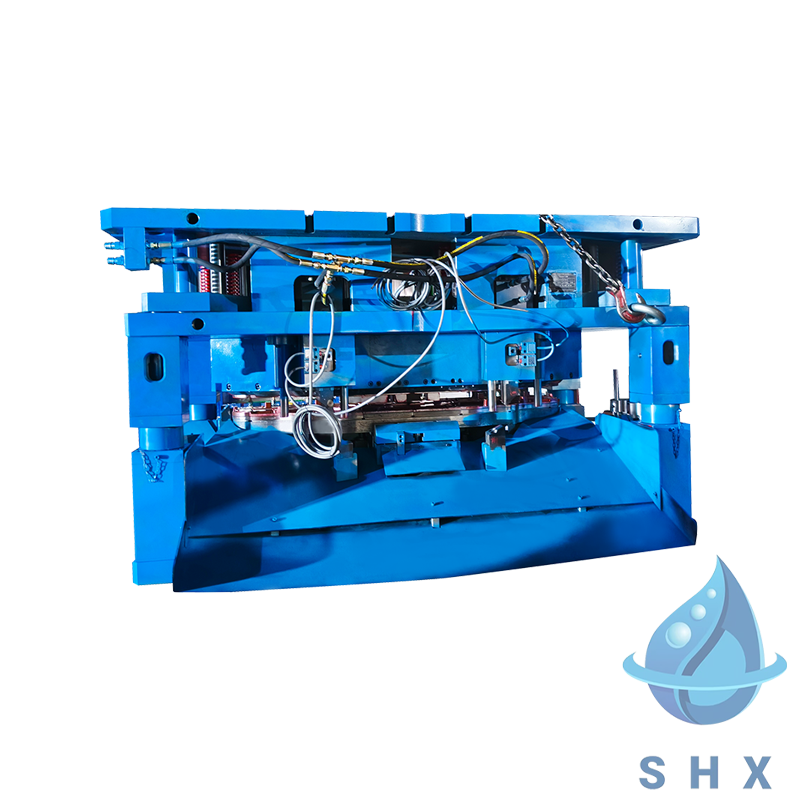

The Trimming Die for the production of Car Bottom Plate is a high-precision tool developed for trimm...

ABOUT US

28YEARS OF

EXPERIENCE

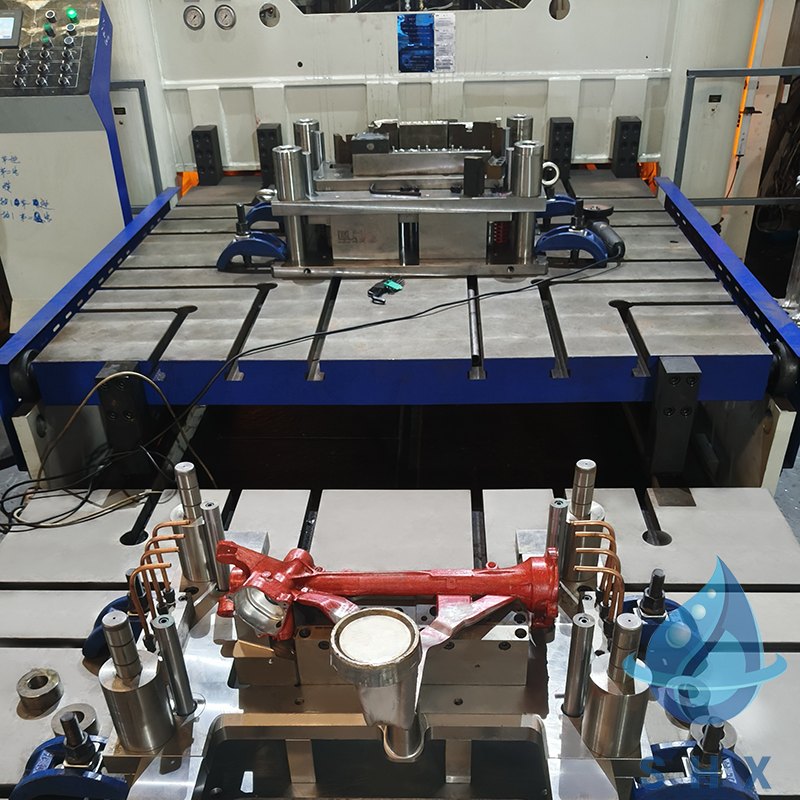

Ningbo Shanghuaxin Machinery Co., Ltd. is a company with a specialization in the research, development, production and sales of aluminums alloy precision die-castings. The company's product range includes electronic components, automotive parts, medical equipment, communication equipment, lighting accessories and other precision industrial components. Guided by a corporate philosophy of "professional and pragmatic, pioneering and innovative, people-oriented, and customer service", the company is market-oriented and committed to meeting customer needs. The company boasts over 50 units of the advanced mold processing center, CNC processing center, aluminum-magnesium alloy die-casting machine, and self-developed automated production equipment. To guarantee that our products meet the quality standards our customers expect, we have established a dedicated testing facility. This center is equipped with cutting-edge 3D measuring technology, 3D image measuring instruments, ROHS coating testers, salt spray test boxes and other advanced testing equipment. The company employs experienced and highly professional R&D technicians, a pragmatic and efficient management team, and standardized management and production processes. It provides a comprehensive range of services, from design and development to post-production processing, surface treatment, and assembly, to ensure product benefits.

Certificate Of Honor

News

Message Feedback

Industry Knowledge Extension

1. What are automotive aluminum die castings?

Automotive aluminum die castings refer to precision metal parts manufactured from aluminum alloys through high-pressure rapid filling. Because aluminum alloy has the advantages of light weight, high strength, corrosion resistance, and good plasticity, it has become an important material in the trend of automobile lightweighting and is widely used in power systems, structural parts, and body parts.

2. Characteristics of aluminum die castings in the automotive industry

(1) Achieve lightweighting of automobiles

The density of aluminum alloy is only one-third that of steel, which can effectively reduce the weight of the vehicle. The lighter the body, the lower the fuel consumption, the longer the battery life, and at the same time, it can improve acceleration performance and handling. Therefore, aluminum die castings have become one of the core materials for new energy vehicles and energy-saving models.

(2) High strength and good dimensional accuracy

The high-pressure casting process allows aluminum liquid to quickly fill the mold cavity, resulting in parts with thin wall thickness, high surface finish, and small dimensional tolerances. It is very suitable for the production of complex structural and endurance parts for automobiles, such as suspension brackets, gearbox housings, motor housings, etc.

(3) High production efficiency and suitable for batch manufacturing

High-pressure die casting can achieve rapid cycle production, and a single mold can produce hundreds of thousands of sets of parts, greatly increasing production capacity and reducing unit cost. It is an ideal process for mass manufacturing in the automotive industry.

(4) High heat dissipation performance and corrosion resistance

Aluminum alloy has excellent thermal conductivity and is suitable for motor housings, radiators and other components. It also has natural antioxidant properties, which can extend the service life of automobile parts.

3. Common faults of automotive aluminum die castings

Automotive aluminum die-casting parts are widely used in engine casings, gearbox casings, chassis structural parts, cooling system parts and other fields due to their advantages such as light weight, high strength, good corrosion resistance, and the ability to realize complex structures. However, during actual production and use, some common faults may still occur in aluminum die-casting parts. These problems will not only affect the appearance of the product, but may also have an impact on assembly accuracy, mechanical performance and the overall reliability of the vehicle. Therefore, understanding the types, causes and effects of these common faults is of great significance to improving die casting quality and service life.

One of the most common failures of aluminum die castings is "porosity and shrinkage cavities." The pores are often caused by the lack of time for gas to be discharged, loose mold clamping, improper injection speed, etc., and appear as unevenly distributed small pores; shrinkage cavities usually occur in thick walls or hot joint areas, which are internal depressions or cavities caused by uneven metal solidification. Such defects may lead to a decrease in the mechanical strength of die castings, and may even cause blast holes during subsequent processing, seriously affecting product reliability.

Secondly, "forming defects such as cold shut and flow marks" are also relatively common. Cold seals are usually linear or seam-like traces caused by low temperature at the front of the metal flow and poor filling, making the structure of aluminum parts potentially vulnerable; flow marks are traces in the direction of metal flow. Although they generally do not affect the strength, they may affect the appearance quality. For automotive trim parts or casings that have high requirements on appearance, such problems must be strictly controlled.

A table of common fault types, possible causes and solutions for automotive aluminum die castings:

| Fault type | Possible reasons | solution |

| pores/bubbles | 1. Poor mold exhaust 2. Molten aluminum has high gas content (such as H₂) 3. The injection speed is too fast and gas is involved |

1. Optimize mold exhaust design 2. Degassing treatment during smelting (such as argon refining) 3. Adjust injection parameters (low speed start) |

| Shrinkage/Porosity | 1. Local wall thickness is too thick leading to uneven cooling 2. Insufficient holding pressure or short holding time 3. Pouring temperature is too high |

1. Optimize structural design and avoid thick and large sections 2. Increase the holding pressure and duration 3. Reduce the pouring temperature |

| Cold shut/flow marks | 1. The molten aluminum temperature is too low 2. Slow injection speed 3. Low mold temperature |

1. Increase molten aluminum and mold temperatures 2. Speed up the injection speed 3. Add mold preheating or heating system |

| Cracks (hot cracking/cold cracking) | 1. Unreasonable alloy composition (such as Fe/Si imbalance) 2. The mold is opened too early or the ejection force is uneven. 3. Internal stress is too large |

1. Adjust alloy composition (such as adding Sr modifier) 2. Extend the cooling time and optimize the ejection system 3. Perform annealing treatment |

FAQ: Frequently Asked Questions about Automotive Aluminum Die Castings

Q1: Why are aluminum die castings commonly used in automobiles?

A: Mainly because aluminum alloy is lightweight, high-strength, and has good heat dissipation, and the die-casting process can realize complex shapes and high-precision parts, which is very suitable for automotive structural parts.

Q2: Will aluminum die castings break easily?

A: No. Modern die-casting parts have high strength and toughness through optimized material ratio and heat treatment, meeting the safety requirements of key automotive structural parts. One-piece die-casting even enhances the overall rigidity of the body.

Q3: What is the difference between aluminum die castings and aluminum extrusions?

A:

Die casting: suitable for complex-shaped, thin-walled, high-precision parts, such as shells and brackets.

Extruded parts: suitable for linear structural parts, such as guide rails and heat sinks.

The two are complementary in cars.

Q4: Are there more aluminum die-casting parts for new energy vehicles?

A: Yes. New energy vehicles use more aluminum materials for battery trays, motor casings, three-electric system casings, etc. Lightweight is very important for battery life.

Q5: Are aluminum die castings environmentally friendly?

A: Aluminum is 100% recyclable, energy-saving and sustainable, and is a very important environmentally friendly material in the automotive industry.

Ningbo Shanghuaxin Machinery Co., Ltd. is a company with a specialization in the research, development, production and sales of aluminums alloy precision die-castings. The company's product range includes electronic components, automotive parts, medical equipment, communication equipment, lighting accessories and other precision industrial components. Guided by a corporate philosophy of "professional and pragmatic, pioneering and innovative, people-oriented, and customer service", the company is market-oriented and committed to meeting customer needs

English

English 中文简体

中文简体

0086-13806506378

0086-13806506378