The die casting industry has been evolving with the introduction of advanced technologies aimed at improving production efficiency, reducing costs, and enhancing product quality. One such technology is automatic trimming, which has proven to be a game changer in die casting mold operations.

What is Automatic Trimming in Die Casting?

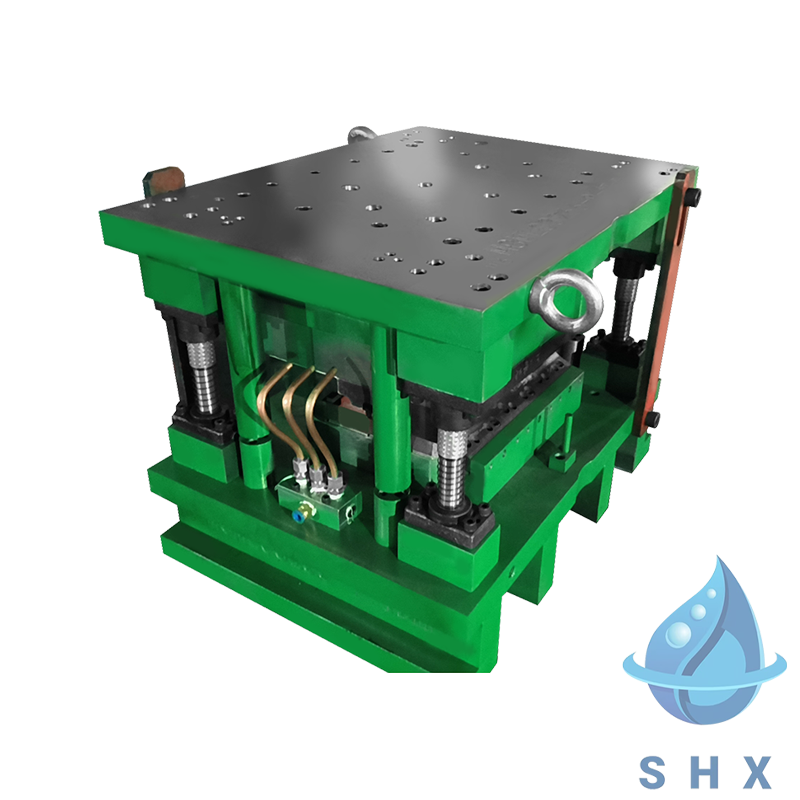

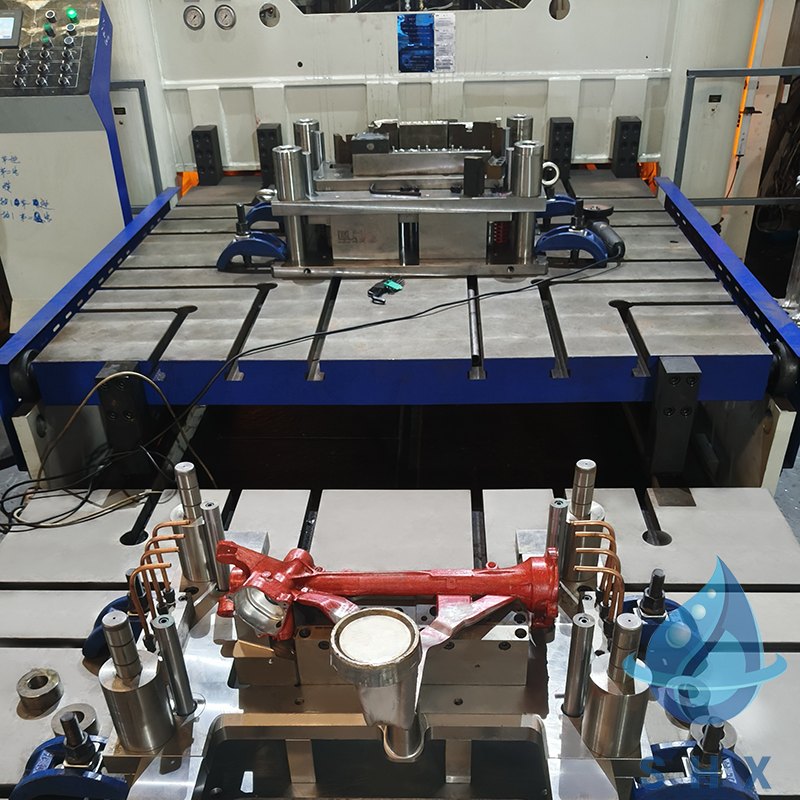

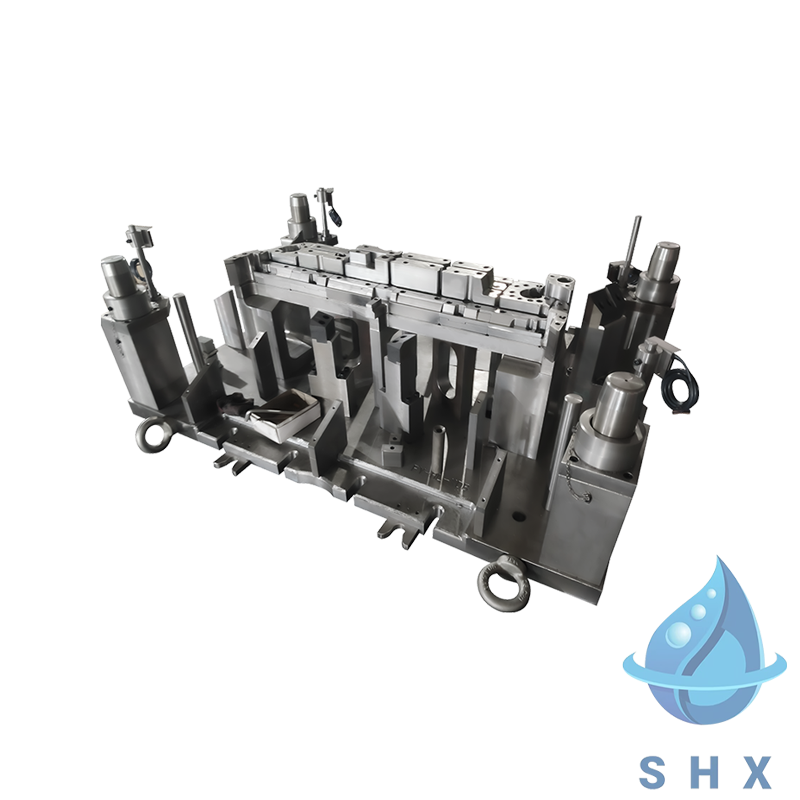

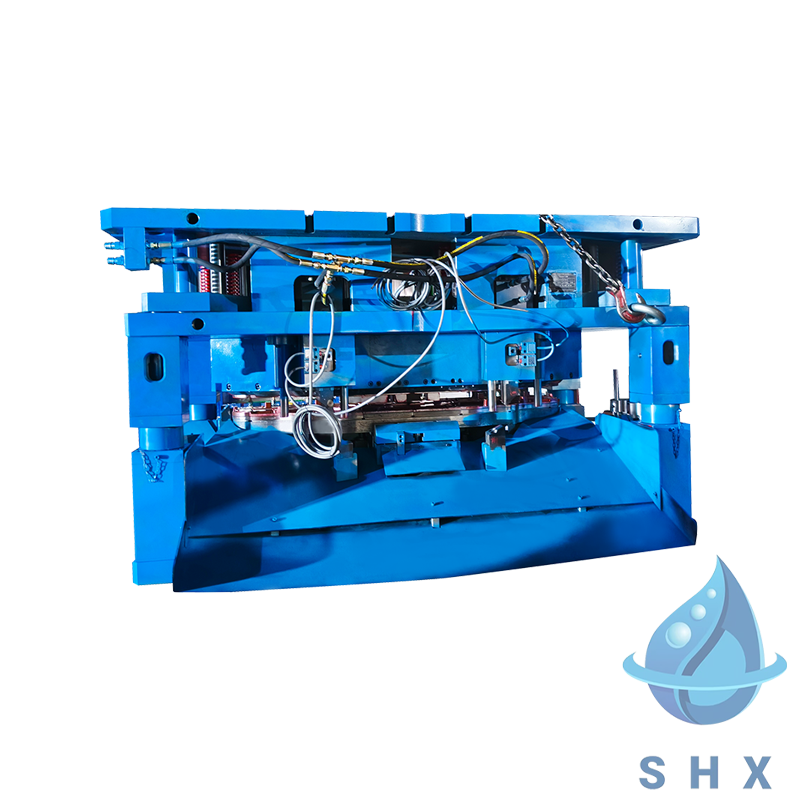

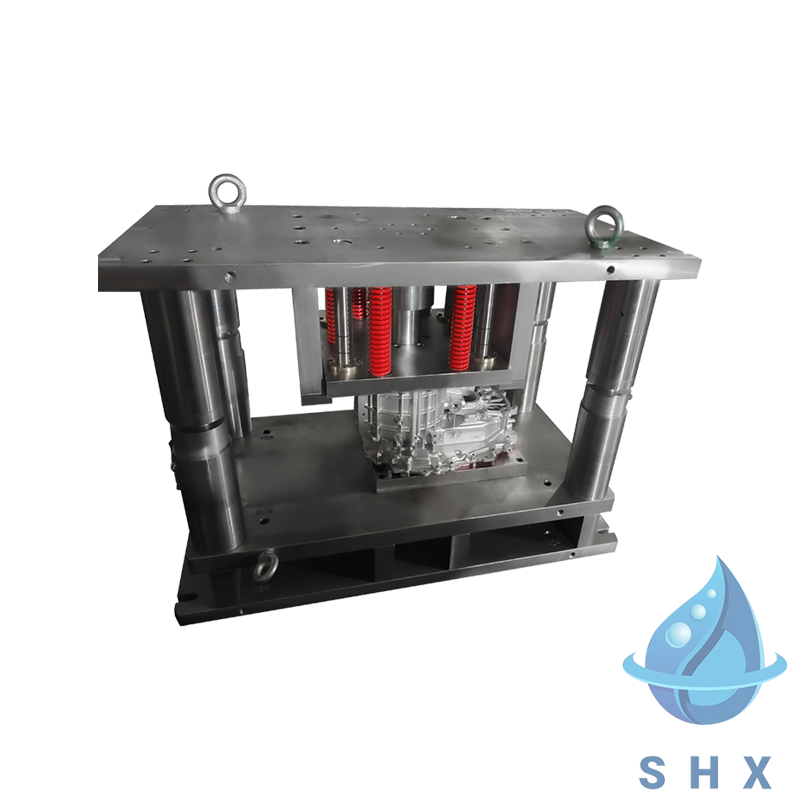

Automatic trimming refers to the use of machines and automated systems to remove excess material or flash from die-cast components after the casting process. This step is crucial in ensuring that the final product meets the required specifications and quality standards. Unlike manual trimming, which is labor-intensive and time-consuming, automatic trimming significantly streamlines the process and reduces human error.

Key Benefits of Automatic Trimming

- Enhanced Efficiency: Automatic trimming machines operate faster than manual methods, allowing for a higher throughput in die casting production.

- Consistency and Precision: Automated systems provide uniform trimming, ensuring that each component meets strict quality standards.

- Cost Reduction: By reducing labor costs and increasing production speed, automatic trimming helps manufacturers lower their overall expenses.

- Improved Product Quality: With consistent trimming, the likelihood of defects such as rough edges or uneven surfaces is minimized, leading to better-quality products.

Automatic Trimming vs. Manual Trimming

To better understand the advantages of automatic trimming, let's compare it with manual trimming, which is the traditional method used in die casting operations.

| Aspect | Automatic Trimming | Manual Trimming |

|---|---|---|

| Speed | Faster, high throughput | Slower, dependent on manual labor |

| Accuracy | Highly accurate, minimal human error | Prone to human error, inconsistencies |

| Cost | Lower long-term costs due to automation | Higher costs due to labor and time |

| Labor | Minimal labor required | Labor-intensive, requires skilled workers |

The Role of Automation in Improving Die Casting Mold Efficiency

Automation in die casting molds, including automatic trimming, plays a crucial role in improving overall efficiency. By reducing the need for manual intervention, automatic systems increase production capacity, reduce errors, and optimize resource utilization.

Reduction in Downtime

Automatic trimming machines are designed for continuous operation, minimizing downtime between production cycles. This results in a significant increase in overall production time, allowing manufacturers to meet higher demand without sacrificing quality.

Lowering the Risk of Defects

Manual trimming is often susceptible to inconsistencies, such as uneven cuts or missed flash, which can lead to defective products. Automatic trimming ensures a uniform and precise result, greatly reducing the chances of producing faulty components.

Improved Resource Management

Automatic trimming not only saves labor costs but also reduces material wastage. With precision cutting, less material is discarded, improving the yield and reducing the environmental footprint of the production process.

Common Applications of Automatic Trimming in Die Casting

Automatic trimming is widely used across various industries, including automotive, aerospace, and electronics, where die-cast components are common. These industries benefit from increased efficiency and product quality through automated trimming processes.

Automotive Industry

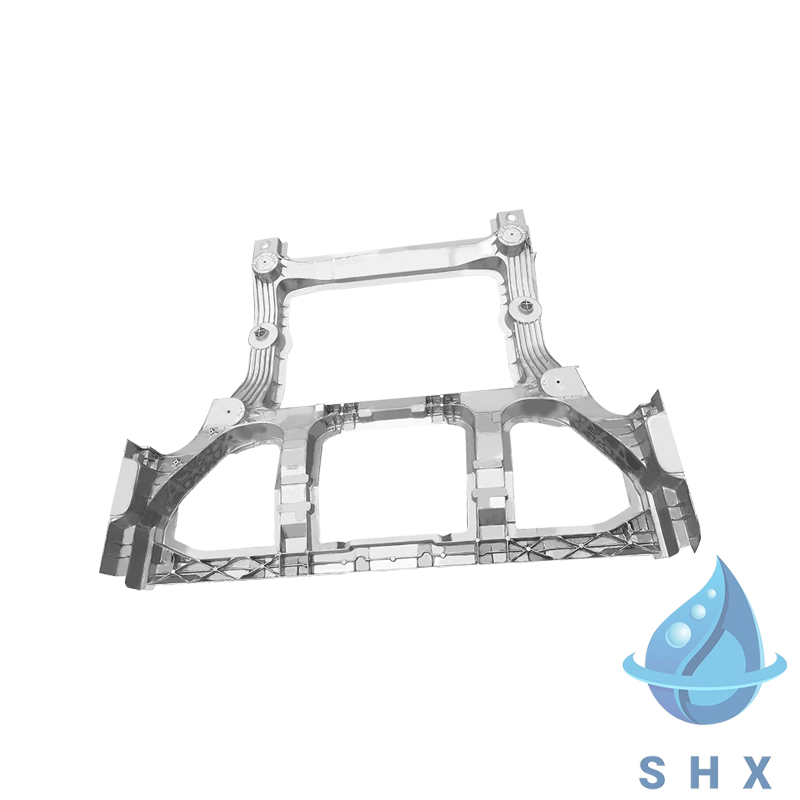

In the automotive industry, where precision and consistency are crucial, automatic trimming is used to process engine parts, transmission components, and various other die-cast parts.

Aerospace Industry

The aerospace industry relies heavily on die-cast parts for manufacturing complex components, where high-quality standards are required. Automatic trimming ensures that every component is free from imperfections, ensuring safety and reliability.

Electronics Industry

In electronics, die-cast parts are used in housing components for devices. Automatic trimming helps achieve the required level of detail and finish, crucial for ensuring product performance and aesthetics.

Frequently Asked Questions (FAQs)

What is the main advantage of automatic trimming over manual trimming?

The main advantage is the significant improvement in speed, consistency, and quality. Automatic trimming increases throughput, reduces human error, and lowers overall production costs.

How does automatic trimming reduce production costs?

Automatic trimming reduces labor costs, minimizes material waste, and optimizes production time, all of which contribute to lower overall expenses in the manufacturing process.

Can automatic trimming be used for all types of die-cast molds?

Yes, automatic trimming can be adapted for various die-cast molds used in different industries, but the setup and machine configuration may vary depending on the material and complexity of the components.

How does automatic trimming improve product quality?

By providing consistent, precise cuts, automatic trimming ensures that every component is free from defects like rough edges or uneven surfaces, leading to higher-quality products.

Conclusion

Automatic trimming has revolutionized the die casting process by offering faster, more consistent, and cost-effective solutions. Its role in improving die casting mold efficiency cannot be overstated, as it contributes to better product quality, lower production costs, and increased operational efficiency. As industries continue to embrace automation, automatic trimming will remain a critical technology in shaping the future of die casting manufacturing.

English

English 中文简体

中文简体

+0086-18158459905

+0086-18158459905