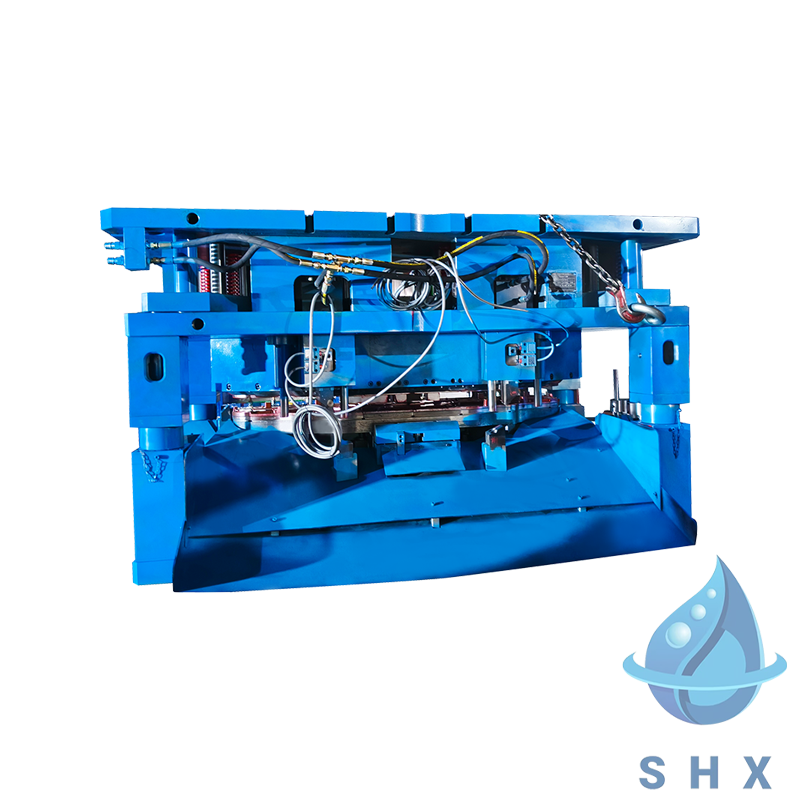

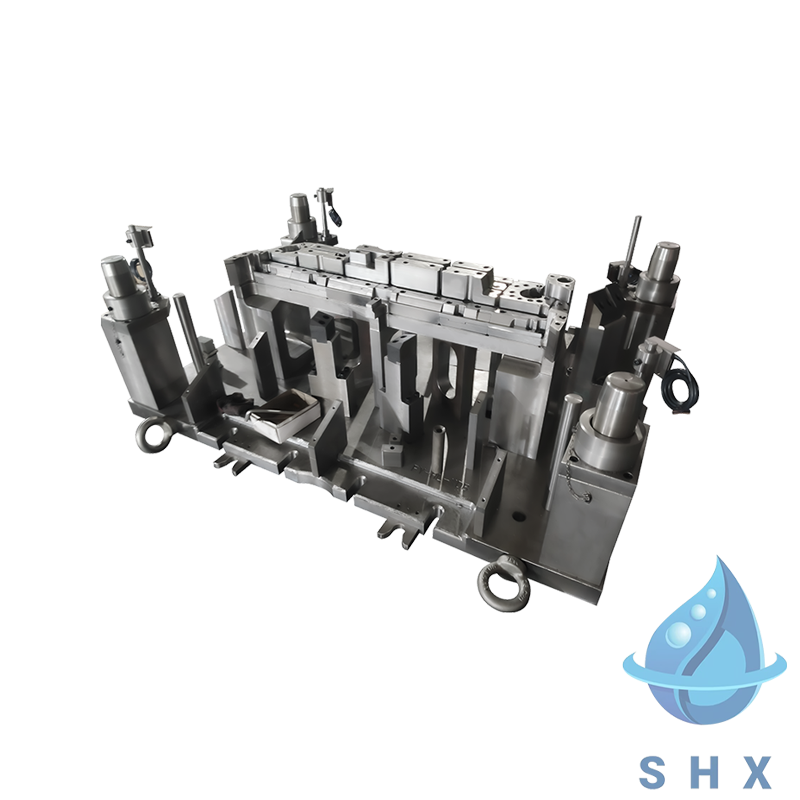

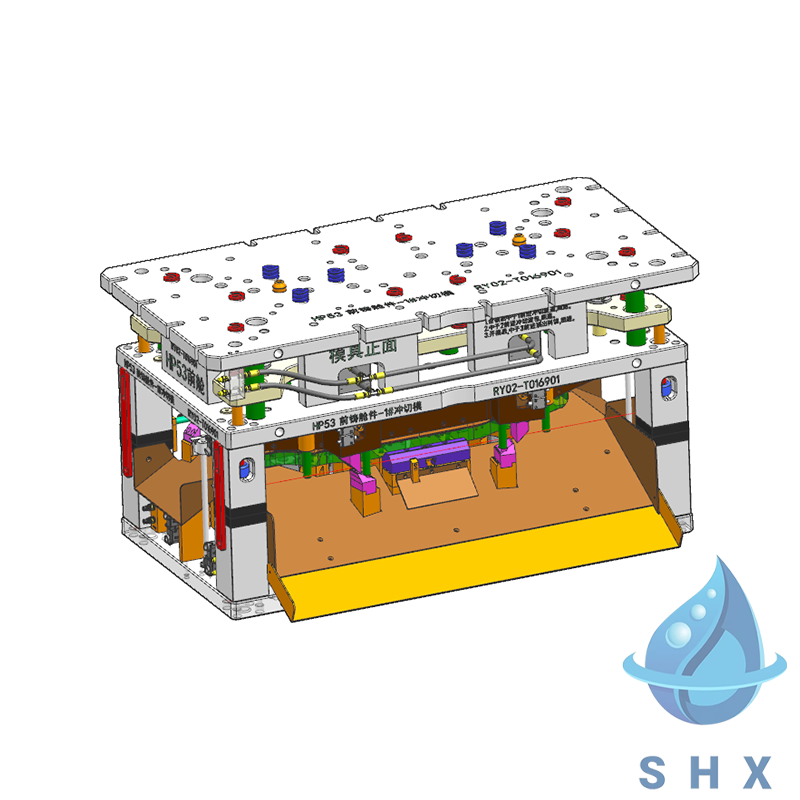

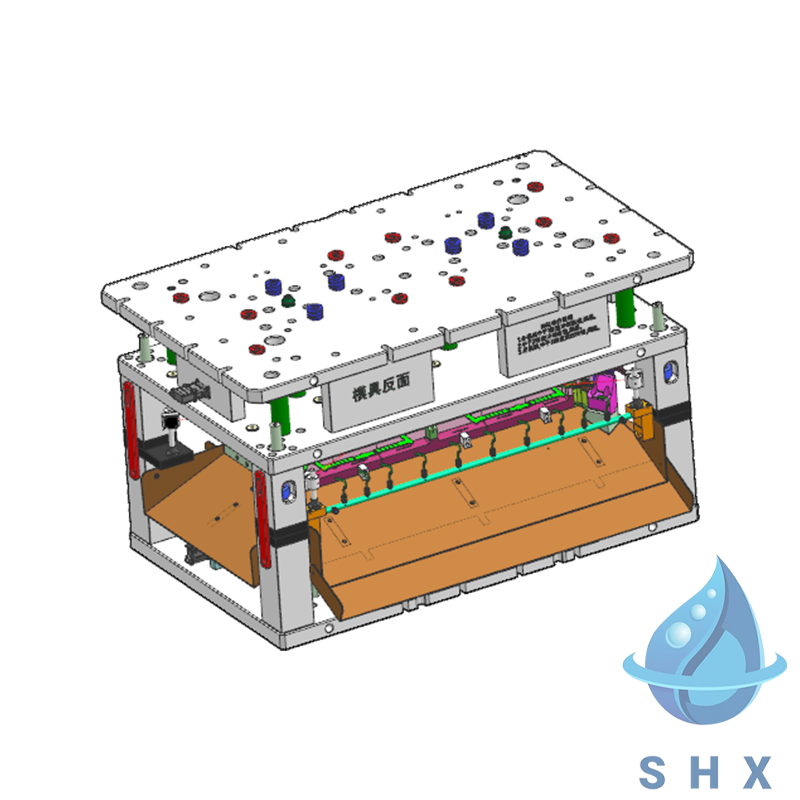

Die casting molds with automatic trimming have become an essential tool in modern manufacturing due to their ability to significantly enhance efficiency and precision. These molds are designed to provide high-quality parts while reducing labor costs and material waste.

What is Die Casting?

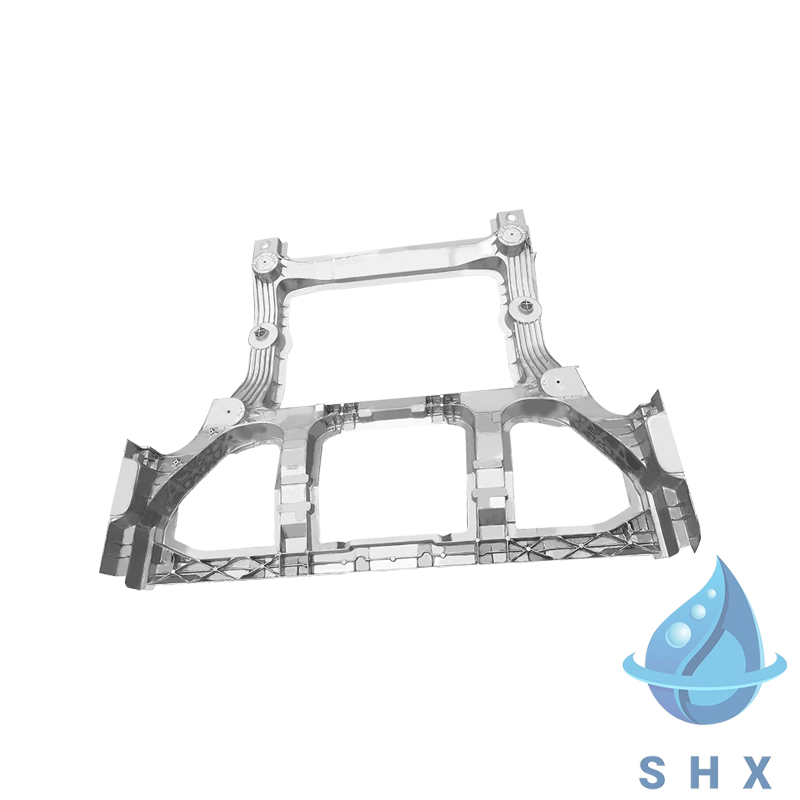

Die casting is a manufacturing process where molten metal is injected into a mold cavity under high pressure. The process allows for the mass production of parts with intricate designs and high precision. It is widely used in industries such as automotive, aerospace, electronics, and more.

Why Automatic Trimming?

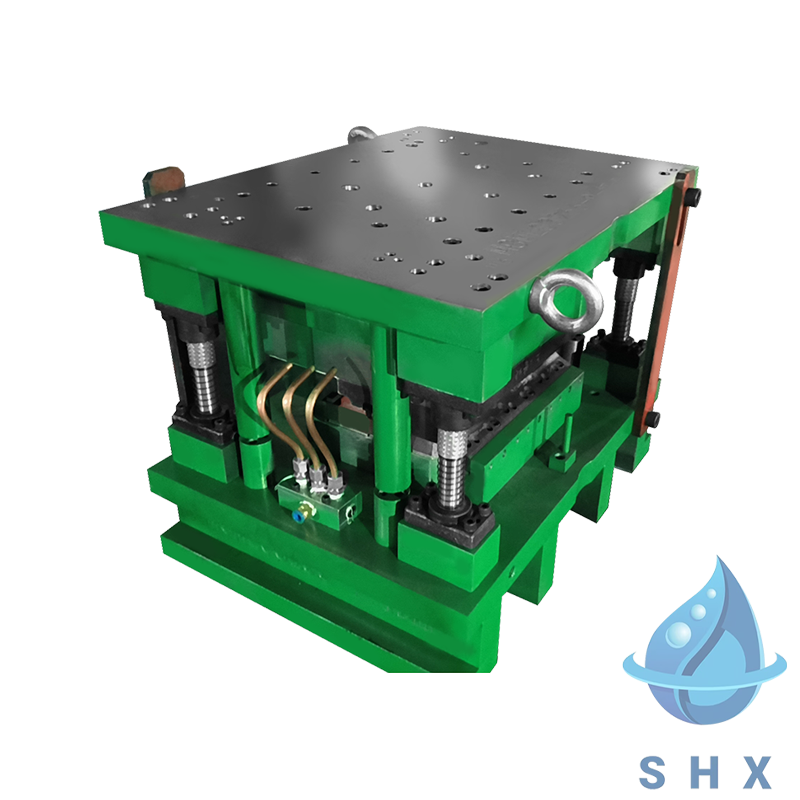

Automatic trimming in die casting molds is a critical innovation aimed at improving operational efficiency. Traditionally, trimming of excess material from the cast parts was done manually. This not only increased the time and labor costs but also introduced the possibility of errors. With automatic trimming, the mold is equipped with mechanisms that trim excess material immediately after the casting process, ensuring consistency and reducing the need for manual intervention.

Key Features of Die Casting Molds with Automatic Trimming

1. Precision and Accuracy

The integration of automatic trimming in die casting molds enhances the precision of the final product. The trimming process is automated to eliminate flash and other imperfections, ensuring a smooth and high-quality finish. This level of precision reduces the need for secondary processes and results in less material wastage.

2. Reduced Labor Costs

By automating the trimming process, manufacturers can significantly reduce labor costs. The need for manual labor is minimized, as the mold performs both the casting and trimming tasks. This not only improves production efficiency but also frees up workers for more value-added activities.

3. Increased Production Speed

Automatic trimming allows for faster turnaround times. The process eliminates the need for manual trimming after casting, allowing parts to be removed from the mold and processed more quickly. This increase in production speed can help manufacturers meet higher demand and improve overall output.

4. Consistency in Product Quality

Since the trimming process is automated, it ensures that each part is trimmed with the same level of precision and accuracy. This consistency leads to better overall product quality, reducing the chances of defects that could arise from human error during manual trimming.

5. Reduced Material Waste

Automatic trimming helps in minimizing material waste by trimming only the excess material necessary. In traditional methods, there could be instances of over-trimming or improper trimming, leading to the loss of valuable material. With automatic trimming, manufacturers can make the most out of their raw materials, improving cost efficiency.

6. Enhanced Mold Durability

Die casting molds with automatic trimming systems are typically designed with high durability in mind. The automatic trimming process places less strain on the mold compared to traditional manual trimming methods, helping to extend the lifespan of the mold. This translates to reduced maintenance costs and longer service life for manufacturers.

Comparison with Traditional Die Casting Molds

| Feature | Traditional Die Casting Mold | Die Casting Mold with Automatic Trimming |

|---|---|---|

| Labor Requirements | High (manual trimming needed) | Low (automatic trimming integrated) |

| Production Speed | Slower (manual trimming delays) | Faster (automatic trimming speeds up production) |

| Material Waste | Higher (manual errors increase waste) | Lower (precise trimming reduces waste) |

| Product Quality Consistency | Varies (manual trimming may cause inconsistencies) | High (automated trimming ensures consistency) |

| Cost Efficiency | Lower (due to higher labor and waste) | Higher (due to reduced labor and waste) |

Frequently Asked Questions (FAQ)

Q1: What types of materials are best suited for die casting molds with automatic trimming?

Die casting molds with automatic trimming are typically used for metals such as aluminum, zinc, and magnesium. These materials offer excellent casting properties and work well with the high-pressure injection process used in die casting.

Q2: How does automatic trimming impact the overall cost of die casting?

While the initial investment in die casting molds with automatic trimming may be higher, the reduction in labor costs, material waste, and production time results in a more cost-effective process in the long run.

Q3: Can automatic trimming be used for complex part designs?

Yes, automatic trimming can handle complex part designs with intricate features, as it ensures consistent trimming based on the exact shape and specifications of the part.

Conclusion

Die casting molds with automatic trimming offer numerous benefits, including reduced labor costs, faster production times, and improved consistency in product quality. By automating the trimming process, manufacturers can significantly enhance efficiency and minimize material waste, making it an ideal solution for industries that require high precision and high-volume production.

English

English 中文简体

中文简体

+0086-18158459905

+0086-18158459905