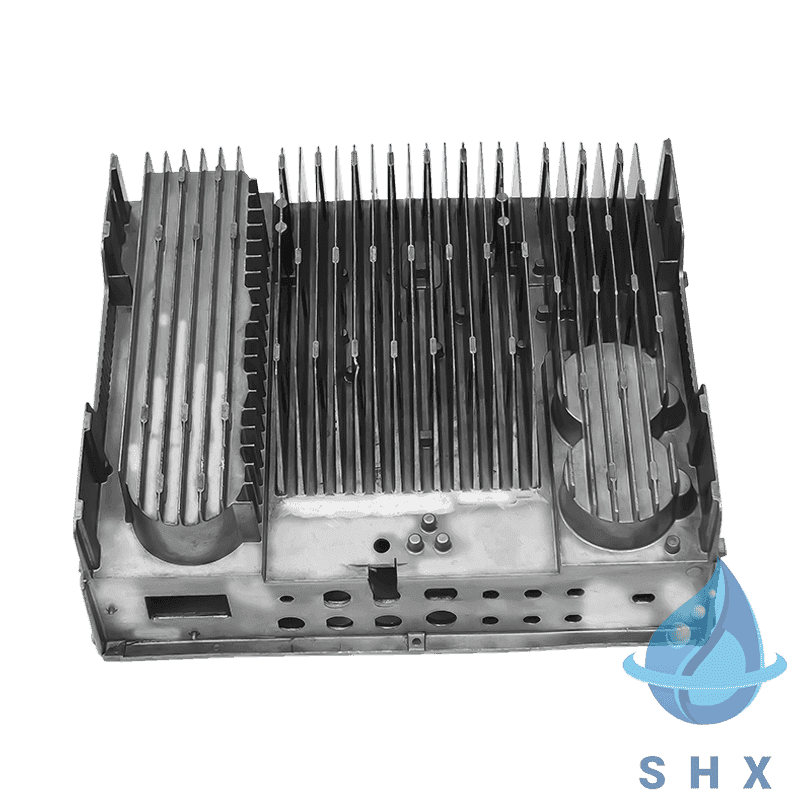

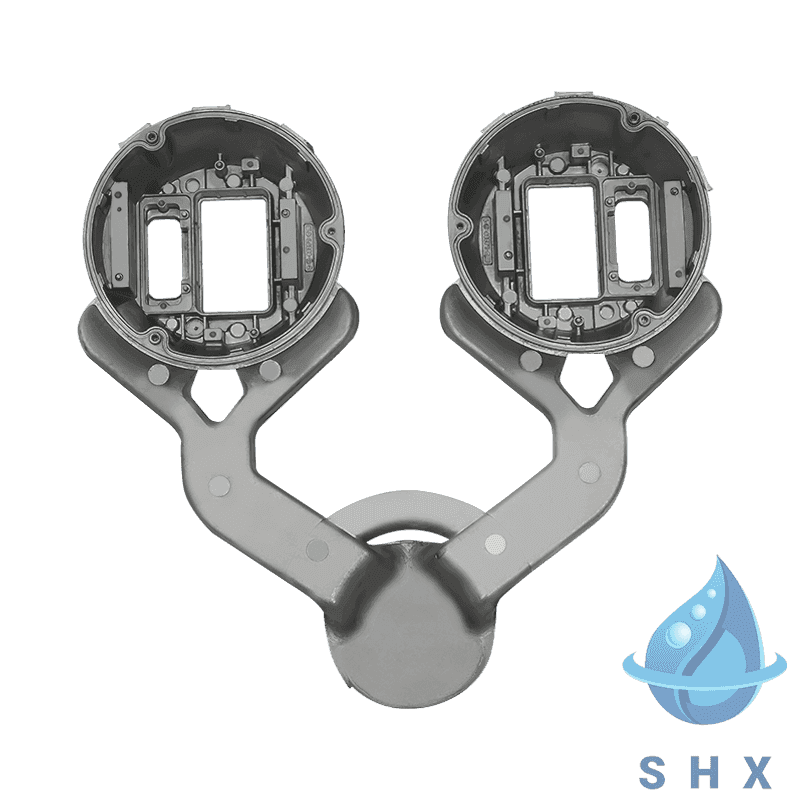

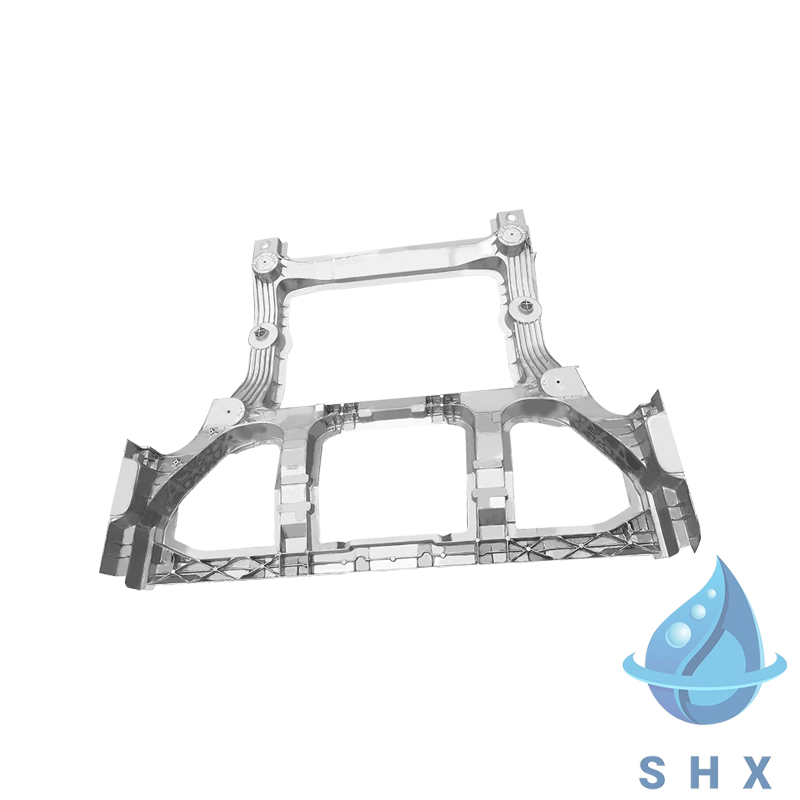

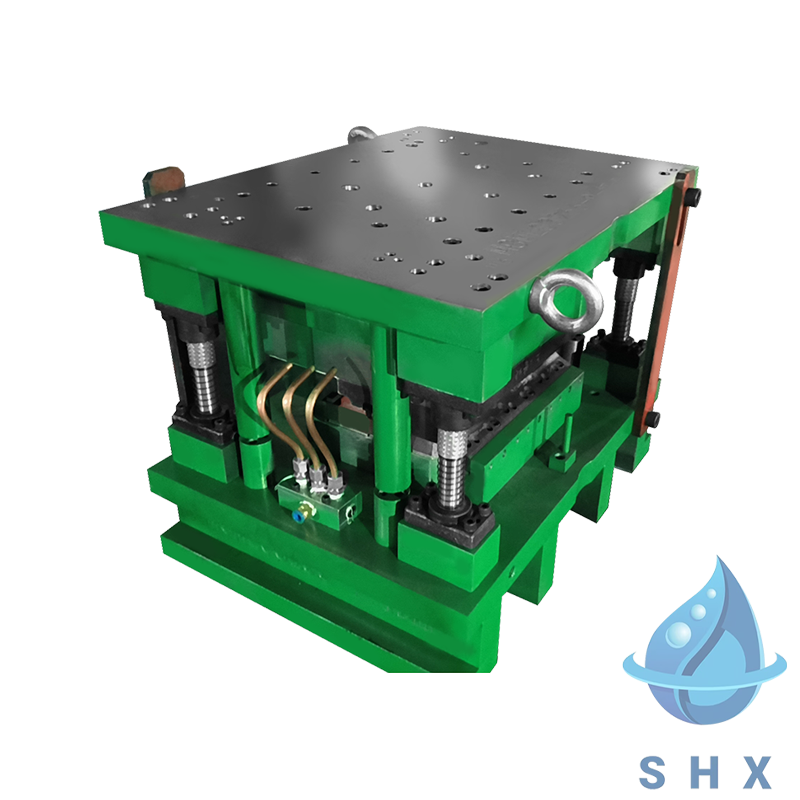

Die casting is a popular manufacturing process for creating metal parts with high precision and smooth surfaces. It involves injecting molten metal into a mold under high pressure to form intricate shapes. Die casting molds play a crucial role in ensuring high-quality production. These molds are typically made of durable materials such as steel or aluminum, which can withstand the heat and pressure of molten metal during the casting process.

Components of a Die Casting Mold

- Cavity: The hollow space where molten metal is injected to form the shape of the part.

- Core: The part of the mold that shapes the internal features of the component, such as holes or indentations.

Types of Die Casting Molds

- Single-Cavity Mold: Used for producing one part per cycle.

- Multi-Cavity Mold: Allows for the production of multiple parts in one cycle, increasing productivity.

- Complex Die Casting Molds: Designed for intricate parts with complex geometries.

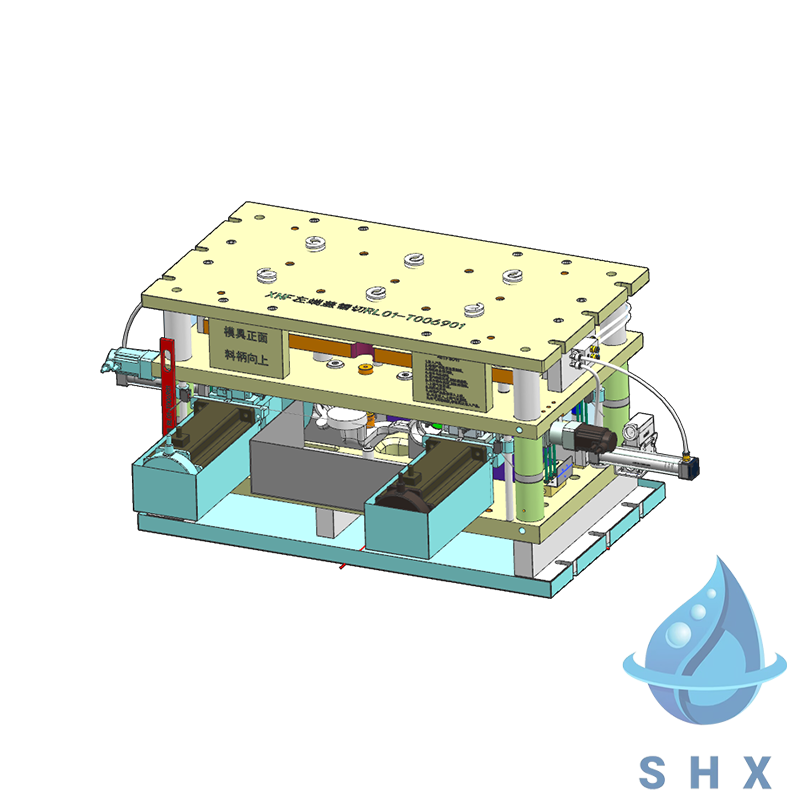

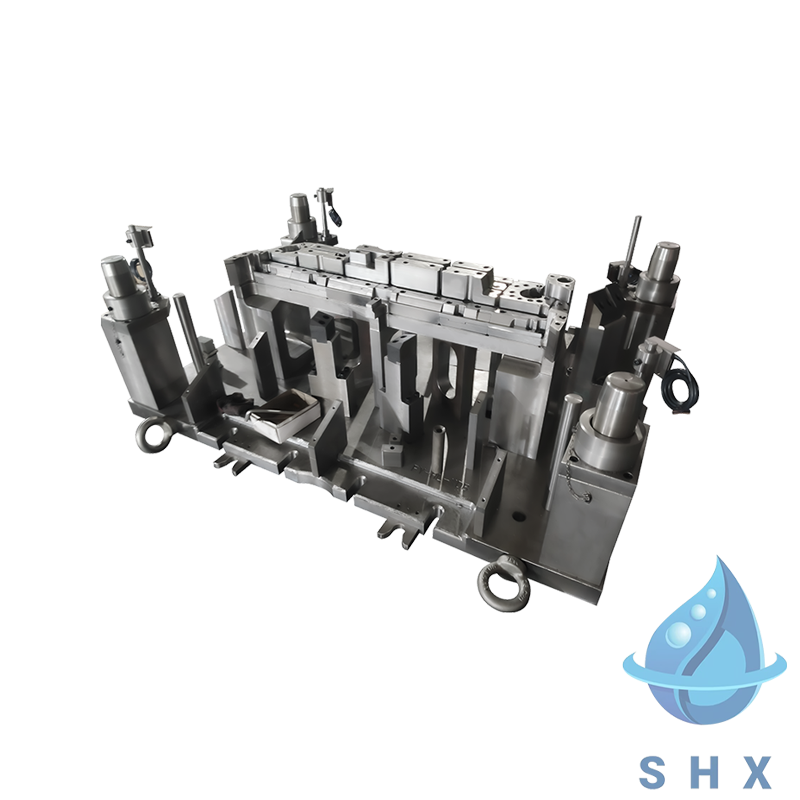

Die Casting Automatic Trimming Molds

Die casting automatic trimming molds are specialized molds used for trimming excess material from cast parts, ensuring they meet the desired specifications. After a part is cast and solidified, trimming molds remove excess material such as flash or sprues, improving the part's finish and performance. The use of automatic trimming molds enhances efficiency by reducing manual labor and increasing the overall speed of production.

How Automatic Trimming Works

Automatic trimming molds operate by using mechanical or hydraulic presses to trim excess material from the part. This process occurs after the die casting process, ensuring that the final part has a clean finish without the need for additional manual intervention.

- Efficiency: Reduces the time required for manual trimming.

- Consistency: Provides uniform trimming, ensuring that all parts meet the same quality standards.

- Cost Savings: Reduces labor costs and minimizes material waste.

Applications of Die Casting Automatic Trimming Molds

Automatic trimming molds are used in industries such as:

- Automotive: To ensure precise and efficient production of automotive components.

- Aerospace: For the production of lightweight and high-precision parts.

- Consumer Electronics: For the manufacture of small components with tight tolerances.

Comparison Between Die Casting Molds and Die Casting Automatic Trimming Molds

The main difference between standard die casting molds and automatic trimming molds lies in their function and application. While both are used in the die casting process, trimming molds specifically address the issue of excess material removal after the initial casting process.

| Aspect | Die Casting Mold | Die Casting Automatic Trimming Mold |

|---|---|---|

| Purpose | Creates the part shape by injecting molten metal. | Removes excess material from the cast part to improve finish. |

| Applications | Used in creating complex metal parts for various industries. | Used in industries requiring high precision and minimal material waste. |

| Process | Involves metal injection and cooling. | Involves trimming excess material post-casting. |

| Efficiency | Efficient in part formation. | Enhances overall production efficiency by automating the trimming process. |

| Cost | Higher initial cost due to complex mold design. | Reduces overall production cost by eliminating manual labor. |

Benefits of Using Die Casting Molds

- High Precision: Die casting molds produce parts with precise dimensions and tight tolerances, ensuring that they fit well within larger systems.

- Efficiency: The process is highly automated, leading to reduced production times and lower labor costs.

- Durability: Molds are designed to handle the high pressures and temperatures of molten metal, making them long-lasting.

- Complex Geometries: Die casting molds allow for the creation of parts with intricate shapes and fine details.

Frequently Asked Questions (FAQs)

What materials are used for die casting molds?

Die casting molds are typically made from materials like high-strength steel, which can withstand the intense pressure and heat involved in the casting process. Some molds may also incorporate materials like aluminum for lighter applications.

How does an automatic trimming mold improve production?

Automatic trimming molds improve production efficiency by eliminating the need for manual trimming, reducing labor costs, and ensuring consistent part quality with minimal material waste.

What industries use die casting molds?

Die casting molds are used in a wide range of industries, including automotive, aerospace, electronics, and consumer goods manufacturing. They are essential for producing high-precision metal parts.

What are the advantages of multi-cavity die casting molds?

Multi-cavity die casting molds allow for the production of multiple parts in a single cycle, improving productivity and reducing costs. This is especially beneficial for mass production runs.

Conclusion

Both die casting molds and die casting automatic trimming molds play vital roles in modern manufacturing. Die casting molds are essential for creating precise parts, while automatic trimming molds enhance the efficiency and quality of production by removing excess material. By understanding their unique functions and applications, manufacturers can make informed decisions that optimize production processes and improve overall efficiency.

English

English 中文简体

中文简体

+0086-18158459905

+0086-18158459905