1. What are energy storage aluminum die-casting parts?

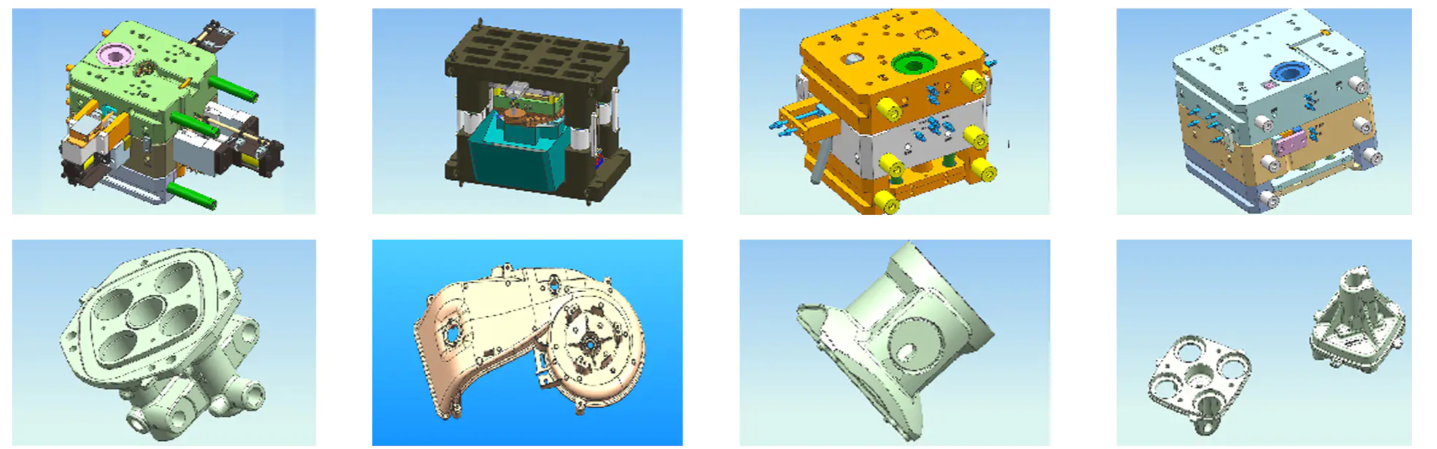

Energy storage aluminum die-casting parts are key structural and functional components used in various energy storage equipment (such as household energy storage systems, commercial and industrial energy storage cabinets, portable power supplies, etc.). These parts are mainly produced through aluminum alloy die-casting processes and have characteristics such as high strength, lightweight, good thermal conductivity, and corrosion resistance, making them an important foundation for the safe, efficient, and stable operation of modern energy storage equipment.

Energy storage aluminum die-casting parts are metal parts formed by injecting molten aluminum alloy into a mold at high pressure and speed. They are typically used in battery module housings, inverter housings, heat dissipation structures, mounting brackets, high-voltage connection structures, etc. Because energy storage systems have extremely high safety requirements, aluminum die-casting parts must not only meet strength requirements but also possess good thermal conductivity to ensure battery cell heat dissipation, safe isolation, and long-term stable operation.

(1) Main Features of Energy Storage Aluminum Die-Casting Parts

Lightweight Design

The low density of aluminum alloy makes the overall weight of energy storage equipment lighter, facilitating handling and installation, especially suitable for household or portable energy storage scenarios.

Superior Heat Dissipation Performance

Energy storage systems generate a large amount of heat during high-power operation. Aluminum alloy has good thermal conductivity, and combined with die-cast heat dissipation structures, it can significantly improve system heat dissipation efficiency.

High Strength and Corrosion Resistance

Aluminum alloy has good corrosion resistance and mechanical strength, enabling it to withstand long-term operation and indoor and outdoor environmental changes, increasing the lifespan of energy storage equipment.

High Molding Accuracy

The die-casting process allows for the one-time molding of complex structures with high dimensional accuracy, suitable for mass production, ensuring consistency and reliability.

(2) Typical Applications of Energy Storage Aluminum Die-Casting Parts

Battery Module Housing: Used for battery cell protection, impact resistance, heat insulation, and fixation.

BMS & Inverter Housing: Provides structural support and heat dissipation functions for the control system.

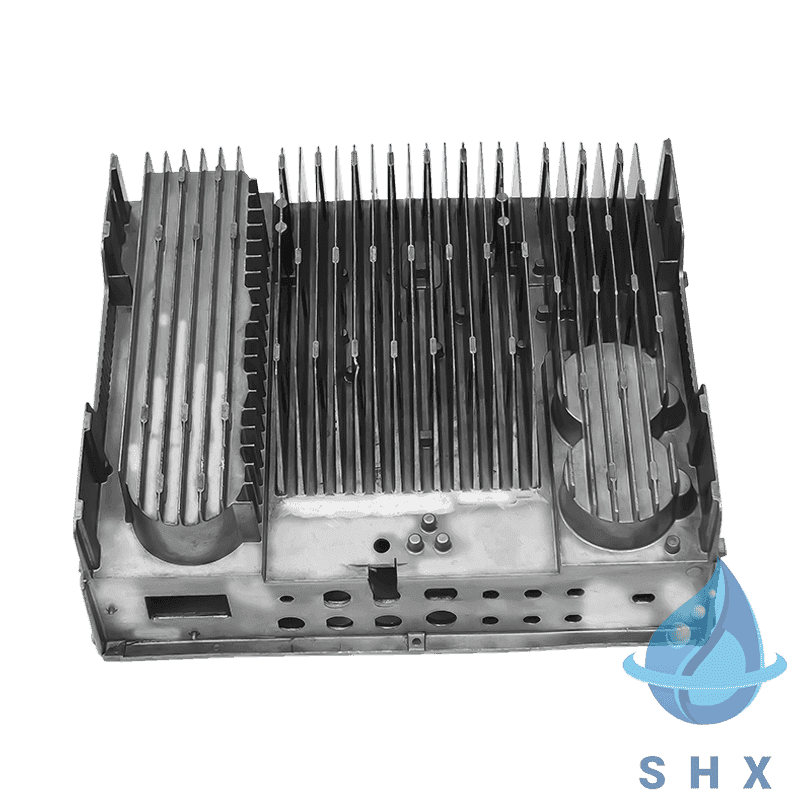

Heat Dissipation Base Plate and Heat Sink: Accelerates heat conduction, ensuring stable operation of the energy storage system under high load conditions.

Connecting Terminals and Structural Components: Used for high-voltage connections, support frames, fixing components, etc.

(3) Why is the energy storage industry increasingly relying on aluminum die-casting parts?

With the rapid growth of the energy storage market, the safety, stability, heat dissipation requirements, and production cost control of equipment have become core concerns. Aluminum die-cast parts can simultaneously meet the demands for lightweight design, high heat dissipation, high strength, and mass production, making them currently the most cost-effective structural component solution in the energy storage industry. Whether for residential energy storage systems or commercial and industrial energy storage cabinets, key structural components are gradually adopting aluminum die-casting solutions.

2. How does aluminum die-casting technology improve the production efficiency of energy storage equipment?

With the rapid growth of the energy storage market, the production scale of energy storage equipment is continuously expanding, and manufacturing enterprises are facing triple pressure in terms of "cost, efficiency, and quality." In this context, aluminum die-casting technology, with its advantages of high-efficiency molding, lightweight design, and excellent heat dissipation and structural performance, has gradually become an indispensable key process in the manufacturing of energy storage equipment. Especially in the production of core components such as battery module housings, heat dissipation structural parts, and inverter housings, aluminum die-casting is becoming the mainstream choice for improving production efficiency. So, how exactly does aluminum die-casting technology improve the production efficiency of energy storage equipment?

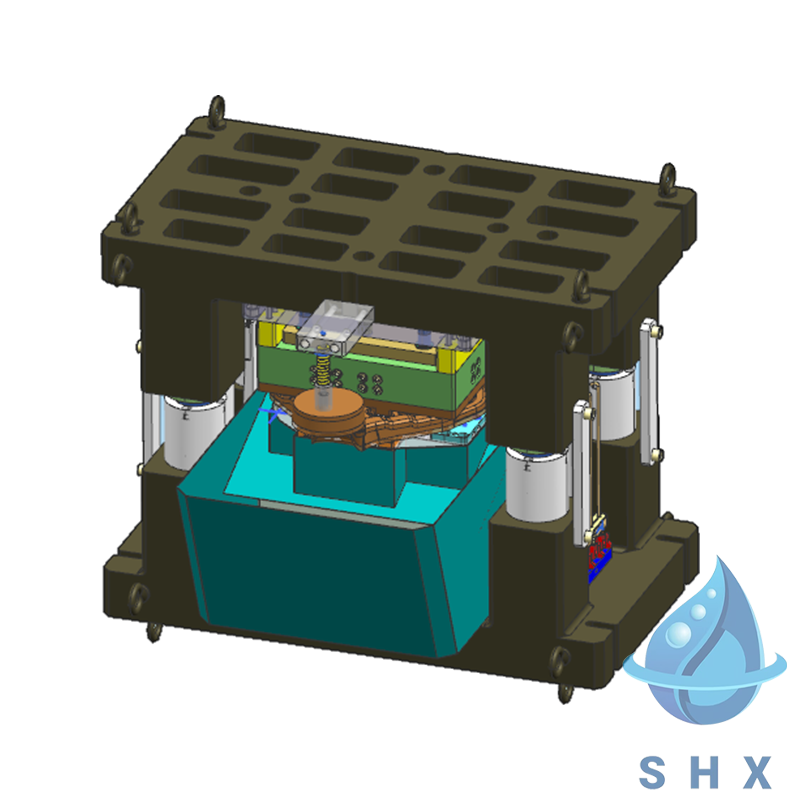

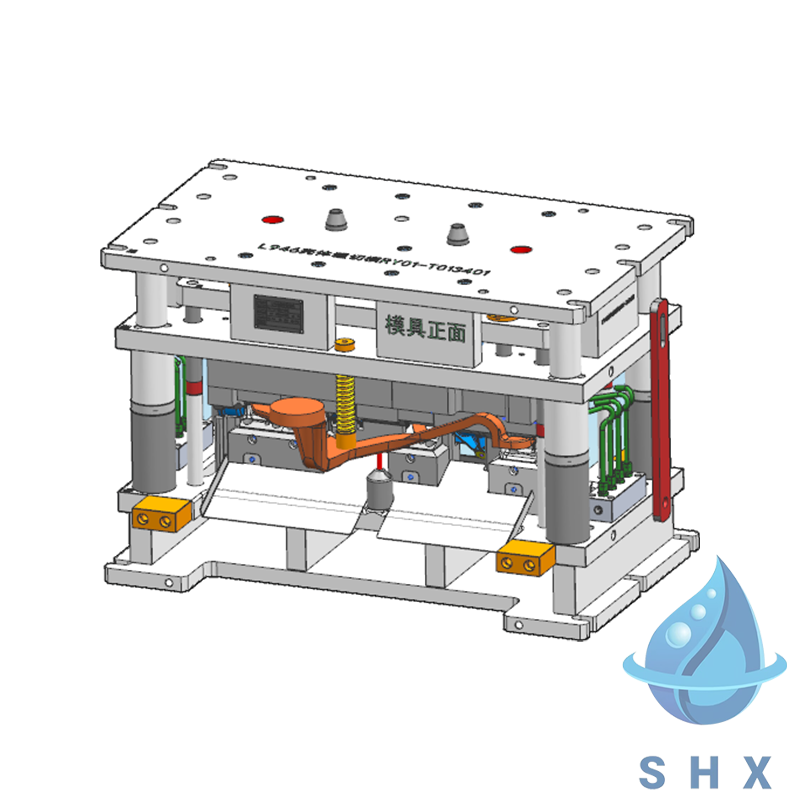

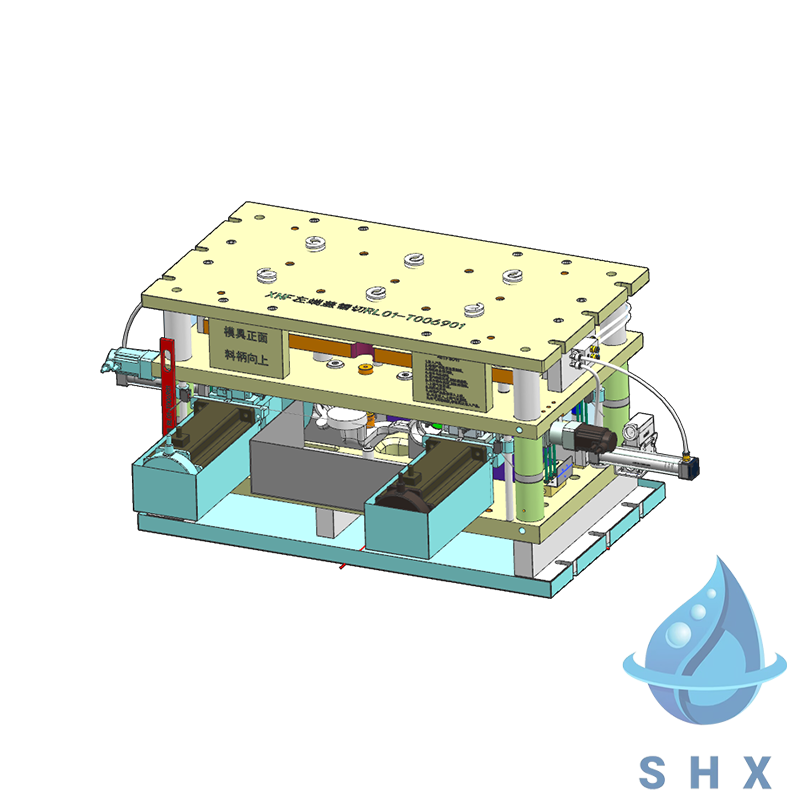

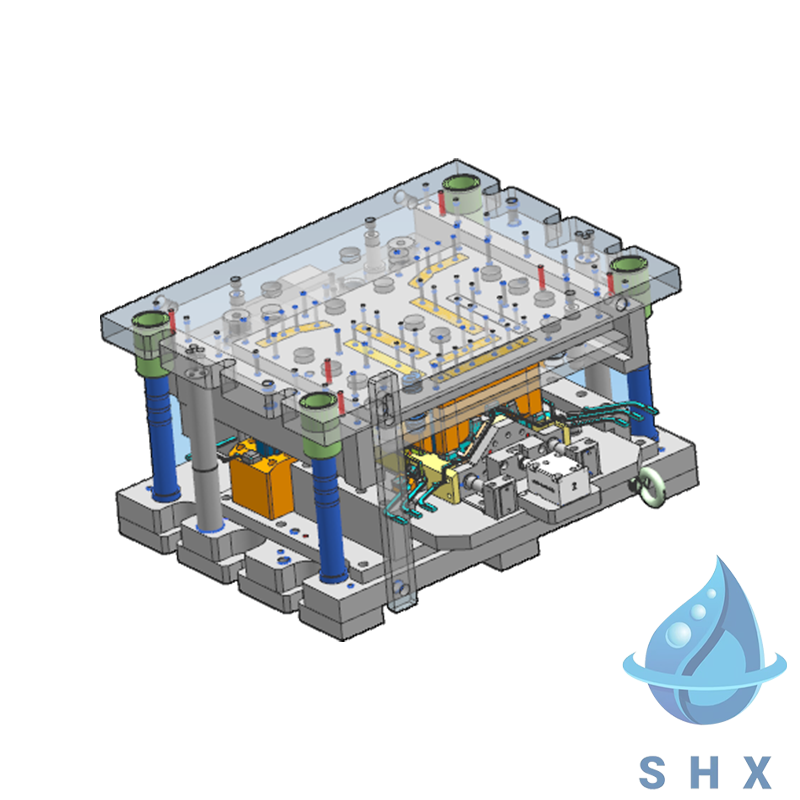

(1) Integrated molding reduces the number of components

Traditional energy storage equipment structural parts often use sheet metal processing, welding, and multi-part assembly methods, which are cumbersome, have high assembly costs, and make it difficult to control part consistency. Aluminum die-casting technology can form complex structures in one go through a mold, integrating multiple parts into a single integral part. For example:

The battery module housing can integrate heat dissipation holes, reinforcing ribs, and mounting positions in one molding process.

The inverter housing can simultaneously form heat sinks, fixing holes, and wire groove structures.

This "integrated design" not only reduces the number of components but also significantly shortens the production cycle, transforming energy storage equipment manufacturing from a multi-step process into a controllable, fast single-step process, thereby significantly improving production capacity.

(2) High molding stability

Key parts of energy storage equipment require extremely high safety, airtightness, and dimensional stability. The aluminum die-casting process uses a high-speed, high-pressure injection method, allowing the molten aluminum to quickly fill the mold cavity and solidify, resulting in high molding accuracy and good structural consistency. This brings two significant advantages:

Stable accuracy: It can meet dimensional requirements of ±0.05mm or even higher, reducing subsequent processing adjustments.

Low defect rate: Reduces scrap problems caused by deformation, welds, and pores.

A lower defect rate means a more efficient production line, less rework, and a smoother production rhythm, thus improving the overall mass manufacturing efficiency of energy storage equipment.

(3) Efficient heat dissipation structure

Energy storage equipment generates a large amount of heat during charging and discharging, and heat dissipation performance directly affects the equipment's lifespan and safety. Aluminum die-casting technology enables the integrated molding of complex heat dissipation structures, such as:

High-density heat dissipation fins

Thermal conduction channels

Heat dissipation base plates

If these structures were manufactured using traditional methods, the cost would be high and the efficiency low, making it difficult to meet the demands of large-scale production. Die-casting, however, can manufacture a large number of high-performance heat dissipation components in a very short time. Better heat dissipation means that equipment design can be more compact, system operation efficiency is higher, and thus indirectly improves the production and assembly efficiency of the entire machine.

(4) Lightweight materials reduce transportation and installation costs

Aluminum alloy materials have low density and high strength, making them particularly suitable for structural components in energy storage systems that require strength but cannot be too heavy. The efficiency improvements brought about by lightweighting are mainly reflected in:

Increased transportation efficiency, with more units carried per batch

Easier handling and positioning during assembly, reducing labor time

Finished products such as portable energy storage and battery modules are easier to assemble into the casing

Lightweighting is not only a technical advantage but also improves overall process efficiency in the supply chain.

(5) Suitable for large-scale stable production

One of the biggest advantages of aluminum die-casting is its suitability for standardized, large-scale manufacturing. Once the mold is developed, it can continuously and mass-produce highly consistent structural components in a short time. Compared with processes such as CNC and welding, die-casting has lower unit production costs and shorter cycles, enabling energy storage manufacturing companies to achieve:

Rapid response to market demand

Shorter customer delivery cycles

Stable supply chain capacity

This is especially important for the rapidly developing energy storage industry.

(6) Further improvement in processing efficiency

Aluminum die-cast parts are usually deburred, machined, and surface treated after molding. Due to the stable dimensions and regular structure of die-cast parts, the efficiency of post-processing is higher. For example:

CNC only needs to perform localized precision machining

Surfaces can be directly coated, electrophoretically coated, or anodized

Automated robots are easier to grasp and position

This makes the entire production chain smoother, increases the automation rate of equipment, and improves overall efficiency.

(7) Gradual standardization of energy storage equipment

Modern energy storage equipment is evolving towards "modularization" and "standardization." Aluminum die-casting can quickly replicate consistent structural components, making modular design of energy storage systems easier. For example:

Standard module casing

Modular inverter housing

Universal heat sink baseplate

Modularity can directly reduce design costs, production costs, and inventory pressure, thereby improving the overall manufacturing efficiency of energy storage equipment.

Aluminum die-casting technology, with its efficient molding, high precision, lightweight properties, and excellent heat dissipation performance, has become a key force in improving production efficiency in the manufacturing of energy storage equipment. From structural integration and mass production to supply chain optimization, aluminum die-casting is helping the energy storage industry accelerate towards a higher quality, lower cost, and more efficient development stage.

3. Common Faults and Solutions for Energy Storage Component Radiators

With the widespread application of energy storage systems in residential, commercial, and large-scale power plants, their safety and stability have gradually become a core concern for the industry. Radiators, as crucial structural components in energy storage systems, perform key functions such as heat conduction, thermal balance management, and equipment protection. If a radiator malfunctions, it can lead to excessive battery temperature, shortened lifespan, and even serious safety issues such as thermal runaway. Therefore, understanding the common faults and solutions for energy storage component radiators is crucial for equipment manufacturers, installers, and maintenance teams.

(1) Radiator Blockage Leading to Reduced Cooling Efficiency

Fault Phenomena:

Large accumulation of dust, oil, or fine particles on the radiator surface

Blockage of the gaps between cooling fins, preventing smooth airflow

System temperature shows a continuous slow increase

High-temperature alarm from the inverter or BMS

Local heating of the energy storage enclosure

Cause Analysis:

Energy storage systems are usually used in outdoor or semi-open environments, where there is a large amount of dust, sand, or oil in the air. These impurities enter the radiator surface with the fan or natural convection, and over time, they can cause fin blockage, significantly reducing cooling efficiency.

Solutions:

1) Regularly clean the radiator surface: Use compressed air or a soft brush to clean dust, avoiding scratching the material with hard objects.

2) Add dust-proof structures: Install filters in the air duct; for dusty environments, use removable protective filters.

3) Check fan airflow: If the airflow is insufficient, replace the fan promptly.

4) Optimize installation location: Avoid locations near the ground or dust sources; it is recommended to install in a location with relatively stable airflow.

(2) Radiator Material Corrosion or Surface Oxidation and Peeling

Fault Phenomena:

White powdery corrosive substances appear on the surface (aluminum oxide)

Rough fin surface, coating peeling

Localized pitting or obvious corrosion pits

Reduced cooling performance, unstable temperature

Cause Analysis:

Energy storage systems may be exposed to wind, sun, high humidity, or salt spray environments. Aluminum radiators, when exposed to moisture, salt, or chemical gases for a long time, will accelerate corrosion. Some low-quality heat sinks are prone to oxidation and corrosion due to unstable alloy composition or inadequate surface treatment.

Solutions:

1) Strengthen surface treatment: Choose methods such as anodizing, electrophoresis, and spraying to improve corrosion resistance.

2) Use corrosion-resistant aluminum alloy materials: such as high-strength aluminum alloys like ADC12, A380, and 6063.

3) Strengthen the sealing of the energy storage system: Ensure an IP65 or higher protection level for outdoor equipment.

4) Regularly check for corrosion; replace the heat sink if corrosion severely affects structural strength.

(3) Heat sink deformation leading to poor contact

Fault phenomenon:

Uneven heat sink base plate, gaps between the heat sink and the battery cell or electronic module

Uneven distribution of thermal grease or thermal pads

Discontinuous heat conduction, abnormally high local temperature

BMS detects significant temperature fluctuations in some battery cells

Cause analysis:

The heat sink may be deformed due to extrusion or impact during production, transportation, or installation. An uneven base plate prevents effective contact with the battery cells, affecting heat conduction efficiency; deformed heat fins due to impact may also reduce ventilation efficiency.

Solutions:

1) Check the flatness of the heat sink: Replace the heat sink immediately if the base plate is uneven.

2) Use higher-strength structural components: Choose heat sink structures that are die-cast and have reinforcing ribs.

3) Optimize handling and packaging methods: Use shock-resistant packaging and avoid stacking heavy objects.

4) Strengthen installation specifications: Avoid over-tightening or uneven force application that can cause deformation.

(4) Thermal interface material (TIM) aging or failure

Fault phenomenon:

Thermal interface material (thermal grease/thermal pad) hardens and cracks

Dry or gaps appear on the contact surface

Reduced heat dissipation effect, increased module temperature

BMS frequently triggers over-temperature limits

Cause analysis:

Thermal interface materials gradually age under the influence of long-term high temperature, temperature cycling, and vibration. Especially in portable energy storage and household energy storage products, frequent start-stop cycles and temperature changes cause the TIM material to gradually degrade.

Solutions:

1) Regularly replace the thermal interface material, especially in high-power equipment.

2) Select high-quality TIM (Thermal Interface Material), such as high-conductivity, anti-aging thermal grease or flexible thermal pads.

3) Ensure stable clamping force, avoiding over-tightening or loosening that could affect material lifespan.

4) Reduce the frequency of temperature cycles and optimize operating strategies in system design.

(5) Insufficient heat dissipation due to fan failure

Fault symptoms:

Fan speed decreases or stops completely

Airflow from the outlet weakens

System temperature rises rapidly under high load

Control system detects a fan alarm

Cause analysis:

As an important part of the active cooling system, fans are prone to failure due to dust accumulation, bearing wear, power supply abnormalities, etc. Some low-quality fans have short lifespans or insufficient high-temperature resistance, making them more susceptible to damage during long-term operation.

Solutions:

1) Regularly clean fan blades and air ducts.

2) Check if the fan power supply lines and drive signals are normal.

3) Replace with high-lifespan industrial-grade fans.

4) Optimize the air duct structure to ensure smooth airflow.

(6) Insufficient system heat dissipation

Fault symptoms:

Temperature remains high for a long time, unable to meet heat dissipation requirements

Obvious hot spots, heat concentrated in one direction

Large temperature difference between multiple cells or modules, affecting lifespan consistency

Equipment operates at reduced frequency, limiting performance

Cause analysis:

If the heat sink design is not scientifically sound during the design phase of the energy storage system, it will lead to insufficient overall heat dissipation capacity. For example: excessively high fin density leading to high air resistance, insufficient fin height, low thermal conductivity of the material, restricted airflow, etc.

Solutions:

1) Re-evaluate the thermal design capacity (TDP) of the heat dissipation structure.

2) Increase the heat dissipation area or optimize the fin shape (e.g., wavy, needle-shaped, etc.).

3) Select aluminum with higher thermal conductivity.

4) Optimize the air duct to ensure that air can effectively pass through the fins.

5) Add auxiliary cooling (such as heat pipes, heat spreaders) if necessary.

The safety and stability of energy storage systems depend on a reliable heat dissipation structure, and the heat sink, as a critical component, will directly affect system performance and even safety if it fails. Therefore, the health status of the heat sink should be given high priority during the manufacturing, installation, and maintenance of energy storage equipment. By promptly identifying problems, employing correct maintenance methods, and selecting high-quality radiator materials and structural designs, it is possible to effectively reduce failure rates, extend equipment lifespan, and ensure the stable operation of energy storage systems in various environments.

Summary table of common faults and solutions for energy storage component radiators:

| Troubleshooting Guide | Possible Causes | Solutions |

| Reduced Cooling Efficiency | 1. Dust accumulation or blockage of heat sink 2. Fan malfunction or insufficient speed 3. Thermal paste aging or drying out |

1. Clean the heat sink to ensure proper ventilation 2. Check the fan power supply or replace the fan 3. Reapply thermal paste |

| Abnormal Noise | 1. Fan bearing wear 2. Fan blade deformation or looseness 3. Resonance phenomenon |

1. Lubricate or replace the fan 2. Adjust or replace the blades 3. Check fixing screws, add vibration damping pads |

| Temperature Sensor Failure | 1. Sensor damage 2. Loose or broken connection wires 3. Software calibration error |

1. Replace the sensor 2. Check and reconnect the wiring 3. Recalibrate or update the control software |

| Leakage (Liquid Cooling System) | 1. Pipe rupture or aging seals 2. Loose connectors 3. Corrosion leading to perforation |

1. Replace damaged pipes or seals 2. Tighten connectors 3. Check coolant composition, replace with corrosion-resistant materials |

| Electrical Short Circuit | 1. Heat sink contacting circuit components 2. Condensation causing short circuit (liquid cooling) 3. Damaged insulation material |

1. Reinstall the heat sink, ensuring isolation 2. Enhance sealing or moisture-proof treatment 3. Replace insulation material |

| Local Overheating | 1. Unreasonable heat sink design 2. Heat pipe failure (e.g., dry burning) 3. Uneven contact surface |

1. Optimize heat sink layout or increase heat dissipation area 2. Replace the heat pipe 3. Polish the contact surface or add thermal pads |

| Control System Failure | 1. Damaged temperature control module 2. Signal transmission interruption 3. Program logic error |

1. Replace the control module |

4. What is the function of a heat sink in energy storage components?

In today's rapidly developing energy storage systems, whether for residential, commercial, or large-scale power plants, the safety and stability of the equipment depend on a crucial component—the heat sink. It is the "temperature management core" of the energy storage system and a vital foundation for maintaining battery performance and ensuring the efficient operation of power conversion equipment. The function of a heat sink goes far beyond simply lowering temperature; it plays an irreplaceable role in system lifespan, safety management, and efficiency improvement.

(1) Ensuring Safe Battery Operation

Batteries are the core of energy storage systems, and battery cells generate a significant amount of heat during charging and discharging. If the heat is not dissipated in time, it will lead to excessively high temperatures, causing a series of risks:

Accelerated aging of battery active materials

Expansion and deformation of battery cells

Accelerated capacity degradation

Risk of thermal runaway, even leading to combustion or explosion

The heat sink, through close contact with the battery module, quickly conducts heat away from the battery cells and then dissipates it from the system through natural or forced air cooling, thus keeping the battery operating within a safe temperature range. This is the primary guarantee for the long-term stable operation of the energy storage system.

(2) Improving System Cooling Efficiency

Energy storage systems contain not only batteries but also electronic devices such as inverters, DC/DC converters, and BMS control boards. These components also continuously generate heat during long-term operation. Insufficient cooling may lead to:

Automatic frequency reduction of the control system

Reduced output power

Reduced inverter efficiency

Premature activation of circuit protection

High-efficiency heat sinks (such as die-cast aluminum heat sinks and extruded aluminum heat sinks) increase the heat dissipation surface area and optimize the airflow path, accelerating the transfer of heat from the heat source to the outside, allowing the equipment to maintain high-efficiency output even under high load. This is especially crucial for equipment operating for extended periods, such as commercial and industrial energy storage systems.

(3) Extending the Lifespan of the Energy Storage System

Temperature has a significant impact on battery life. Studies show that:

For every 10℃ increase in battery temperature, the lifespan may be shortened by 30%-50%

Uneven temperature distribution can exacerbate cell inconsistency

Heat sinks effectively maintain temperature consistency among batteries, preventing certain cells from aging prematurely due to prolonged high temperatures, thus extending the lifespan of the entire battery pack. Furthermore, electronic components age faster at high temperatures. The function of a heat sink is to allow each component to operate stably at a "comfortable temperature," reducing maintenance frequency and replacement costs.

(4) Improving System Energy Efficiency

Heat dissipation performance is directly related to energy storage efficiency.

For example:

High inverter temperature → decreased conversion efficiency

Increased MOSFET and IGBT temperature → increased internal resistance → increased power loss

Frequent load reduction under over-temperature protection by the BMS → the energy storage system cannot operate at maximum power

Heat sinks quickly dissipate heat from power devices, allowing the equipment to operate within the optimal temperature range, thereby improving overall system efficiency. For large energy storage power plants, the energy efficiency improvement brought about by optimized heat dissipation is significant and can directly reduce operating costs.

(5) Maintaining Temperature Balance

Energy storage systems are often composed of thousands of battery cells. If the temperature is uneven, it will cause:

Inconsistent charging and discharging capabilities of battery cells

Difficulty in balancing the SOC algorithm

Limited battery module capacity

The appearance of "weakest link cells" dragging down the performance of the entire pack

Heat sinks are responsible not only for cooling but also for temperature balance management.

Through a uniform heat conduction path, the heat sink allows battery cells at different locations to maintain relatively consistent temperatures, achieving:

More stable cycle life

More precise BMS control

Higher battery utilization rate

This is crucial for large energy storage systems.

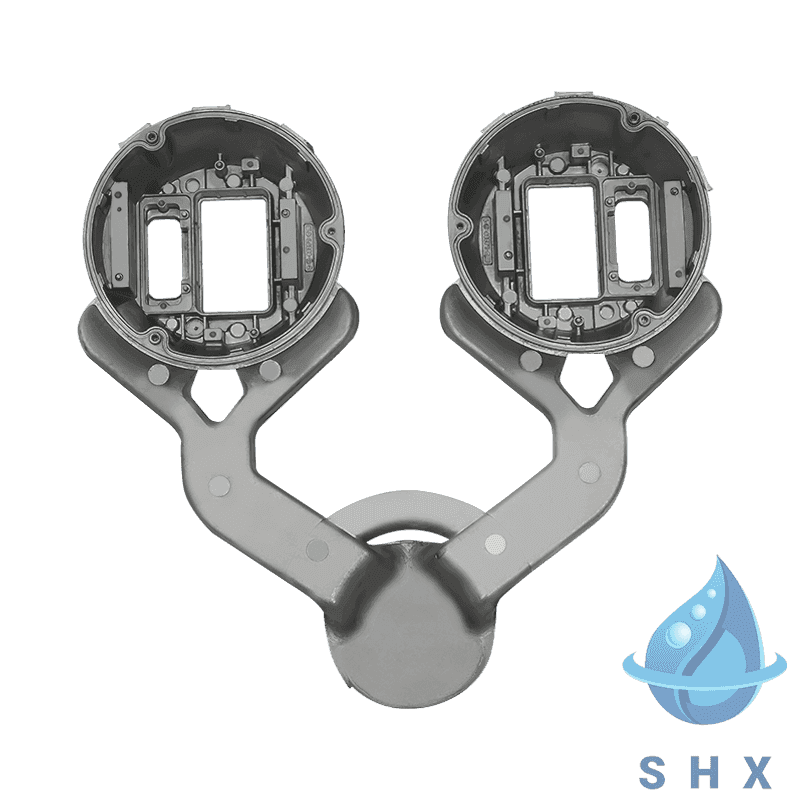

(6) Enhancing Equipment Structural Strength

Energy storage heat sinks are mostly processed using aluminum alloy die-casting or aluminum extrusion processes, possessing the structural advantages of high strength and light weight. In many energy storage devices, the heat sink also serves as a "structural component," such as:

As the base plate of the battery module

As part of the inverter housing

As a heat dissipation support frame

Integrated with the outer casing into an "integrated structure"

This integrated structural design not only reduces the number of components but also improves installation efficiency and operational reliability.

The heat sink of an energy storage component is not just a "heat dissipation device," but also a core foundation for the reliable operation of the entire energy storage system. From reducing battery temperature and improving system efficiency to extending equipment life and enhancing environmental adaptability, it plays an irreplaceable role in the stable, safe, and efficient operation of energy storage systems.

As energy storage equipment develops towards higher power and higher energy density, the performance requirements for heat sinks will become increasingly demanding. High thermal conductivity materials, integrated die-casting structures, and intelligent thermal management will become new trends in heat sink design.

5. Energy Storage Component Radiator FAQ

Energy storage systems contain a large number of batteries, power electronics, and control units. These core components continuously generate heat during operation, so efficient radiators are an important part of ensuring the safe, stable, and efficient operation of energy storage equipment.

(1) What is an energy storage component radiator? What are its main functions?

An energy storage component radiator is a heat dissipation component used for battery modules, inverters, BMS, power modules, and other components in energy storage systems. It is often made of aluminum alloy material and effectively conducts and dissipates heat to the outside through structural design, thereby reducing equipment temperature.

Main functions include:

Reducing battery cell temperature to prevent overheating and thermal runaway

Improving the operating efficiency of inverters and power electronics

Maintaining consistent battery temperature differences and improving cycle life

Improving system stability and operational safety

Extending the overall lifespan of the energy storage system

The radiator is an indispensable core component of energy storage system thermal management.

(2) Why must energy storage systems be equipped with radiators?

Energy storage systems continuously generate heat during charging and discharging. Insufficient heat dissipation may lead to the following problems:

Accelerated battery degradation, reducing lifespan by more than 30%

Battery cell expansion or swelling, posing safety hazards

Control system frequency reduction and load reduction, affecting performance output

Overheating and failure of power devices (MOSFETs, IGBTs, capacitors, etc.)

Large energy storage systems may experience localized overheating, leading to the risk of thermal runaway

Radiators ensure that the system operates within a safe temperature range, which is an important guarantee for reducing risks and ensuring performance.

(3) What are the common design structures of energy storage radiators?

Depending on the specific energy storage application requirements, heatsink structures typically include:

1) Die-cast heatsinks

Supports integrated molding of complex structures

Can integrate reinforcing ribs, mounting positions, and wire grooves

High strength, suitable for mass production

2) Aluminum extruded heatsinks

Suitable for large-area heat dissipation fin structures

Lower manufacturing cost

Stable natural convection cooling performance

3) Combined cooling modules

Heatsink + heat pipe / vapor chamber

Suitable for high-power inverters

4) Liquid-cooled heatsink baseplate (for large-scale energy storage)

Removes heat through coolant circulation

Strong heat dissipation capacity, but more complex structure

Different structures correspond to different power levels and application scenarios; selection should be based on comprehensive consideration of system load and space design.

(4) In which energy storage components are heatsinks mainly used?

Heatsinks are widely used in energy storage systems, mainly including:

Battery module heatsink baseplate

Inverter cooling module

PCS (Power Conversion System) heatsink

BMS control board heatsink

DC/DC converter heatsink

Chassis side panel cooling structure

Portable energy storage power supply cooling module

The design of the heatsink directly affects the operating temperature of every critical component in the energy storage system.

(5) What are the cooling methods for energy storage heatsinks?

Mainly include:

1) Natural convection cooling (commonly used in residential energy storage)

No fan required

Simple structure, long lifespan

Suitable for low-power equipment

2) Forced air cooling (commonly used in inverters)

Uses a fan to increase airflow

Higher cooling efficiency

Suitable for long-term high-power operation

3) Liquid cooling

Large heat capacity, highest cooling efficiency

Precise temperature control

Higher equipment cost

Choosing the appropriate cooling method based on power density is key to improving system efficiency.

(6) What situations indicate that a heatsink needs repair or replacement?

Common fault signals include:

Continuously high and fluctuating temperature

Severe blockage and dust accumulation on cooling fins

Corrosion, oxidation, and peeling of the casing

Deformation of the heatsink baseplate leading to poor contact

Insufficient fan airflow or abnormal noise

Aging of thermal grease or thermal pads

Local temperature significantly higher than other areas

If any of the above situations occur, the heatsink should be inspected or replaced promptly to avoid greater safety hazards.

(7) How to improve the cooling efficiency of energy storage heatsinks?

Performance can be improved in the following ways:

Using aluminum with a higher thermal conductivity

Optimizing fin design to improve airflow efficiency

Reasonable layout of heat dissipation direction and airflow channels

Selecting high-thermal conductivity TIM (thermal grease, thermal pads)

Using a die-cast integrated structure to improve thermal continuity

Ensuring the radiator surface is clean

Regularly checking fans and filters

Both design optimization and maintenance are crucial for achieving long-term stable heat dissipation.

(8) Do energy storage radiators require regular maintenance?

Yes, especially for long-term operating commercial and industrial energy storage systems. Maintenance items include:

Cleaning the heat dissipation fins

Checking the fan's operating status

Replacing aging thermal grease or thermal pads

Checking for radiator deformation

Checking for corrosion or coating peeling

Performing maintenance every 6-12 months can significantly improve system stability and reduce failure rates.

(9) How to choose a suitable energy storage radiator?

When selecting, consider:

Power density and thermal design power (TDP)

Radiator material and manufacturing process

Cooling method: natural cooling, air cooling, or liquid cooling

Equipment structural space and installation method

Whether an integrated structure is needed (such as a die-cast heat sink base)

Environmental factors (outdoor salt spray, dust, humidity)

Budget and production cycle

An excellent radiator should strike a balance between thermal conductivity, structural strength, corrosion resistance, and cost.

Energy storage component radiators are critical to the stable operation of energy storage systems. They not only handle temperature control tasks but also affect battery life, system efficiency, and safety. By understanding common problems, structural characteristics, and selection principles of radiators, users can better manage energy storage systems, reduce maintenance risks, and improve overall performance.

English

English 中文简体

中文简体

+0086-18158459905

+0086-18158459905