1. What is camera aluminum die casting?

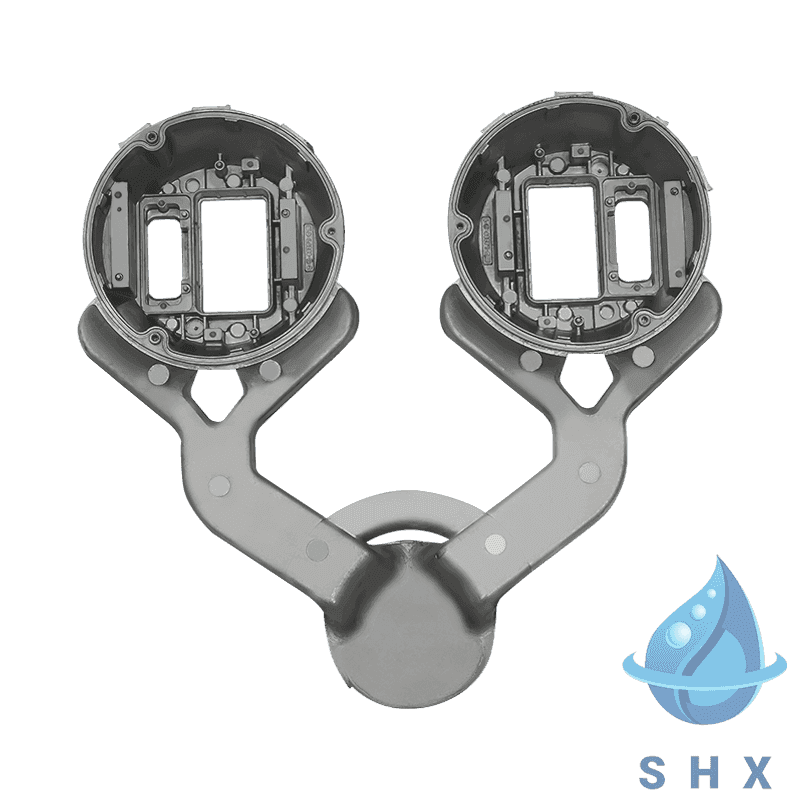

Camera aluminum die-casting parts are camera structural parts made of aluminum alloy materials through the die-casting process, including camera housings, internal mounting frames, lens accessories, heat dissipation components, base supports, etc.

Aluminum die-casting is a manufacturing process that rapidly injects molten aluminum into precision molds under high pressure. It has the characteristics of high molding accuracy, dense structure, and can be mass-produced. It is very suitable for consumer electronics products that require extremely high size, strength, and appearance.

Modern digital cameras, mirrorless cameras, SLR cameras, action cameras and industrial vision equipment generally use aluminum die-casting as the main structural material to ensure that the products are lightweight, durable and have excellent appearance and texture.

2. What is the function of camera aluminum die-casting parts?

(1) Provide structural support and protection

The camera contains precision components such as sensors, lenses, circuit boards, and shutter mechanisms, which require stable and solid structural frame support. Aluminum die-casting can be used as the body frame to ensure that the camera has sufficient strength and protection during use and drops.

(2) Maintain precision assembly and optical alignment

The camera structure must strictly control the dimensions and tolerances, especially the lens mount, focusing system slide rail, and sensor installation position, which require extremely high positional accuracy.

Aluminum die-casting has good dimensional stability, and then undergoes CNC finishing to ensure precise alignment of the optical system.

(3) Improve heat dissipation performance

The CMOS sensor, image processing chip, and image stabilization system generate a lot of heat when shooting for long periods of time.

Aluminum alloy has excellent thermal conductivity, and through optimized structural design (heat sink, reinforcement ribs, etc.), it can help the camera dissipate heat quickly and improve durability.

3. Advantages of camera aluminum die castings

(1) Light weight and high strength

Aluminum alloy has low density but good mechanical strength, making it easier to achieve lightweight camera design while maintaining strength and rigidity.

(2) High molding accuracy, suitable for precision components

High-pressure die casting can achieve high-precision manufacturing of complex three-dimensional structures, and is suitable for assembly holes, structural skeletons, guide rail systems and other high-demand components.

(3) Stable structure and not easily deformed

Aluminum die-casting parts are dense internally and have a uniform structure. They can withstand long-term use, temperature changes and vibrations, and are not prone to deformation or adverse displacement.

(4) Good heat dissipation performance

Aluminum alloy conducts heat quickly and can effectively help dissipate heat from the core components of the camera, ensuring stable continuous shooting, reducing noise and extending the life of the device.

4. Table of common faults of camera aluminum die-casting parts

| Fault type |

Possible reasons |

solution |

| Dimensions out of tolerance (high precision requirements) |

1. Shrinkage and deformation of thin-walled structures (such as bayonet flange flatness >0.05mm)

2. Insufficient compensation for thermal expansion of the mold

3. Post-processing datum offset |

1. Mold flow analysis to optimize the pouring system (shrinkage rate is 1.0-1.2%)

2. The mold is made of hot work steel (such as DAC55) + constant temperature control (±3℃)

3. 3D scanning compensation before CNC processing |

| Surface defects (appearance parts) |

1. Flow marks/cold shut affect the effect of sandblasting anodes

2. Release agent residue causes oxidation and blooming

3. Insufficient mold polishing (Ra>0.4μm) |

1. Adjust the high-speed injection section (speed 3-5m/s)

2. Use water-based release agent + ultrasonic cleaning

3. Mold mirror polishing (Ra≤0.2μm) |

| Insufficient thread strength |

1. Shrinkage at the root of the thread (common for small threads below M1.6)

2. The alloy has low elongation (such as ADC12 elongation <3%)

3. Tooth chipping after tapping |

1. Local extrusion of thread parts + ultrasonic flaw detection

2. Switch to AlSi7Mg (elongation >8%)

3. Switch to self-tapping threading or insert technology |

| Electromagnetic shielding failure |

1. Porosity inside the die casting causes interruption of conductive continuity

2. The surface oxide film is too thick (>20μm)

3. Insufficient alloy purity (such as Fe>0.8%) |

1. Vacuum die casting + conductivity test (>30% IACS)

2. Control the thickness of anodized film (5-10μm)

3. Use high purity aluminum ingots (99.7%) |

| Assembly interference (complex structures) |

1. The cumulative tolerance of multiple components exceeds the limit.

2. Residual stress in die castings causes aging deformation

3. Insert positioning offset (such as copper nut) |

1. Use integrated die-casting to reduce the assembly surface

2. Vibration aging treatment (VSR)

3. In-mold implantation of visual positioning system |

5. Frequently Asked Questions about Camera Aluminum Die Castings

Q1: Why are camera aluminum die-castings more popular than plastic casings?

Because the aluminum alloy structure has higher strength, better heat dissipation, strong impact resistance, and can present a high-grade metal texture, it is the mainstream material for high-end cameras.

Q2: Will aluminum die-casting affect the weight of the camera?

No significant weight gain. Aluminum alloys are much lighter than steel and stronger than plastic, giving them the best balance between lightweight and durability.

Q3: How high precision can the camera aluminum die-casting achieve?

After die-casting + CNC finishing, it can achieve very strict tolerance requirements and meet the assembly accuracy of core parts such as the lens mount and sensor holder.

Q4: Are camera aluminum die castings prone to defects? How to avoid it?

Common defects include blowholes, shrinkage and surface scratches. These problems can be effectively reduced through vacuum die casting, optimized mold design and strict quality control.

English

English 中文简体

中文简体

0086-13806506378

0086-13806506378