1. Detailed Explanation of the Application of Aluminum Die-Casting Parts in the Automotive, Energy Storage, and Camera Industries

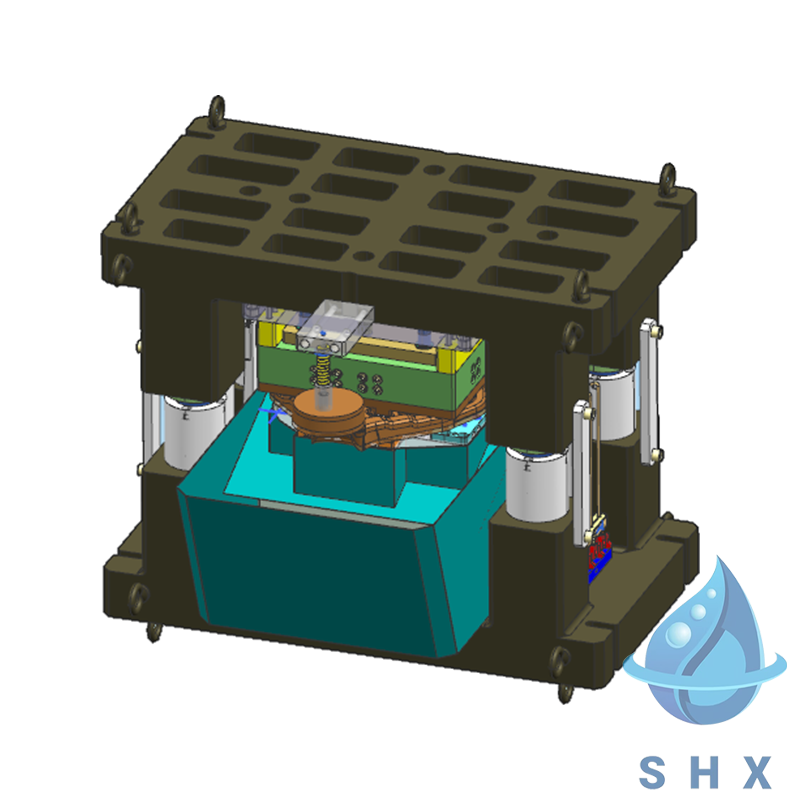

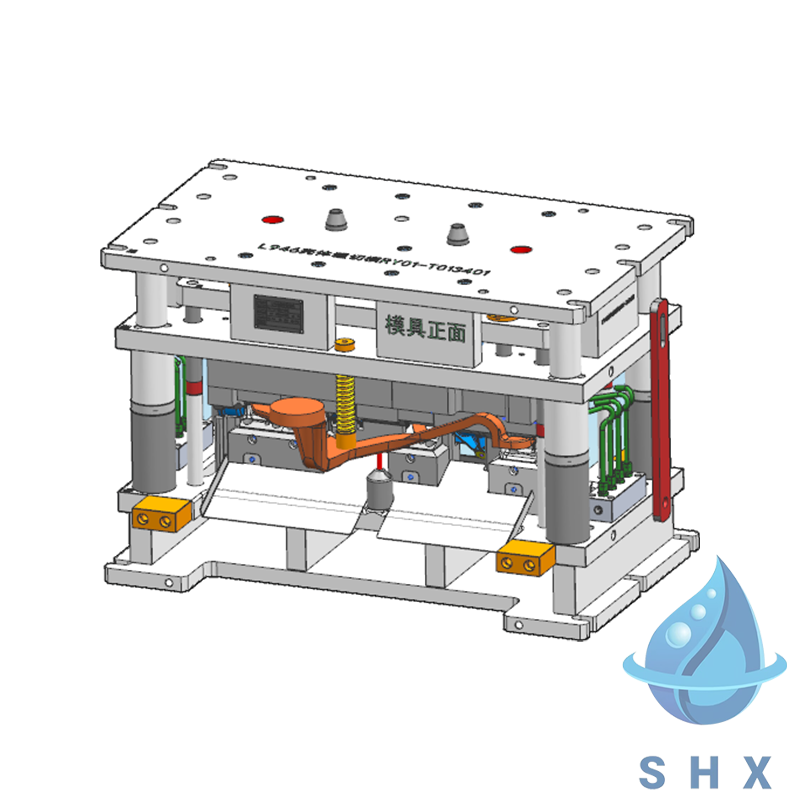

Aluminum die-casting parts play an important role in many industrial fields due to their lightweight, high strength, excellent heat dissipation performance, and high-precision molding capabilities. Especially in the fields of automotive manufacturing, energy storage equipment, and high-end cameras, aluminum die-casting has become one of the irreplaceable core manufacturing methods.

The following introduces three typical application scenarios:

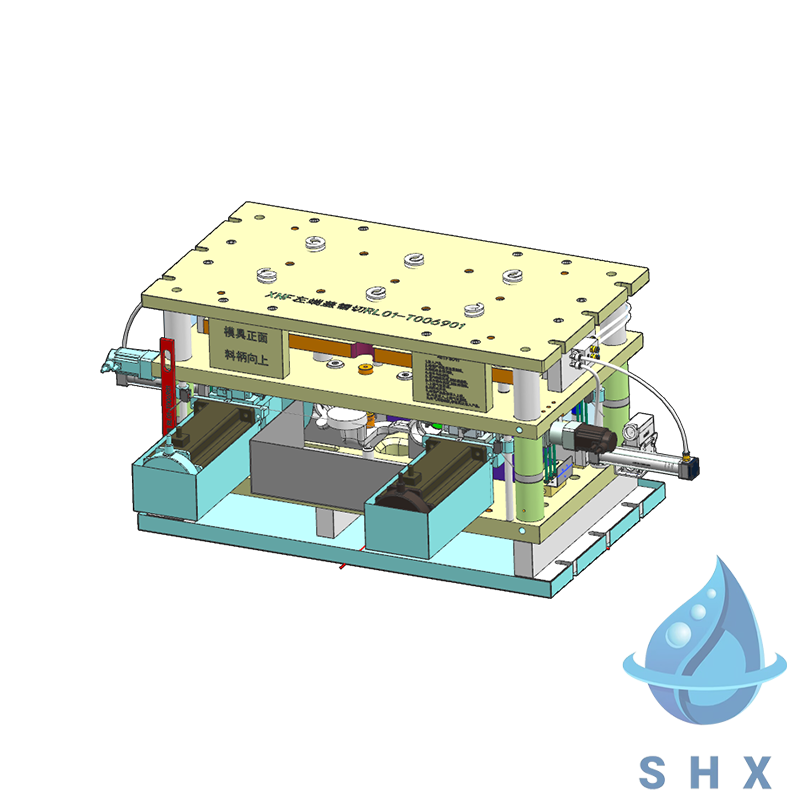

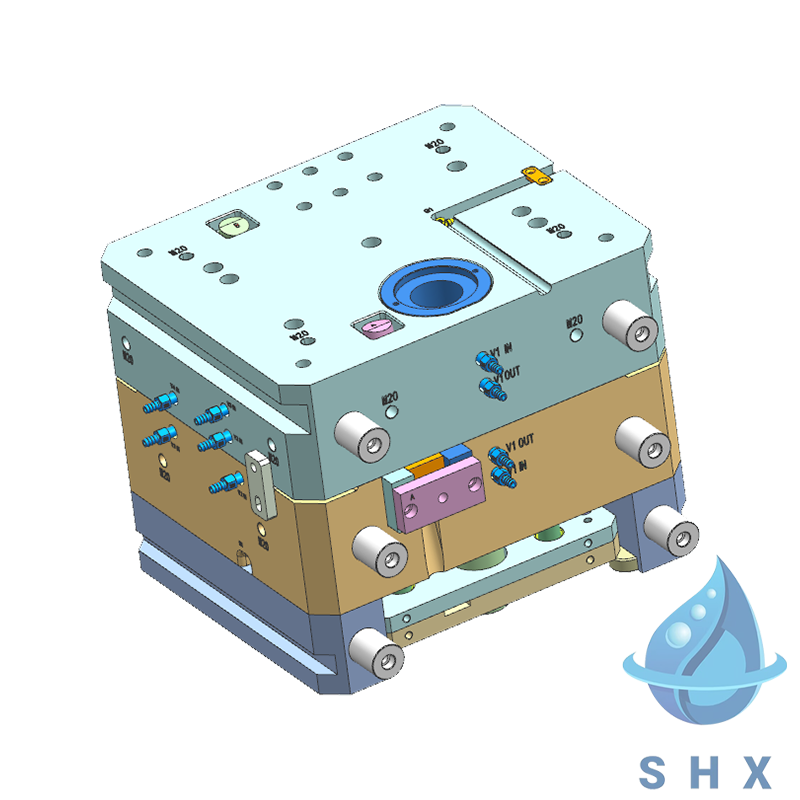

(1) Automotive Aluminum Die-Casting Parts

Automotive aluminum die-casting parts are widely used in engine systems, gearbox housings, suspension systems, electric vehicle motor housings, controller housings, etc., and are an important foundation for achieving lightweighting and energy conservation and emission reduction in automobiles.

Main functions include:

Lightweighting: Aluminum has a density only one-third that of steel, which can significantly reduce the weight of the entire vehicle, improve range and fuel economy.

High structural strength: High-pressure die-cast aluminum parts can withstand complex stress environments and are suitable for safety components. Excellent heat dissipation efficiency: Beneficial for the long-term stable operation of core components in new energy vehicles such as motors and inverters.

Complex structures formed in one piece: Reduces processing steps, improves production efficiency, and lowers costs.

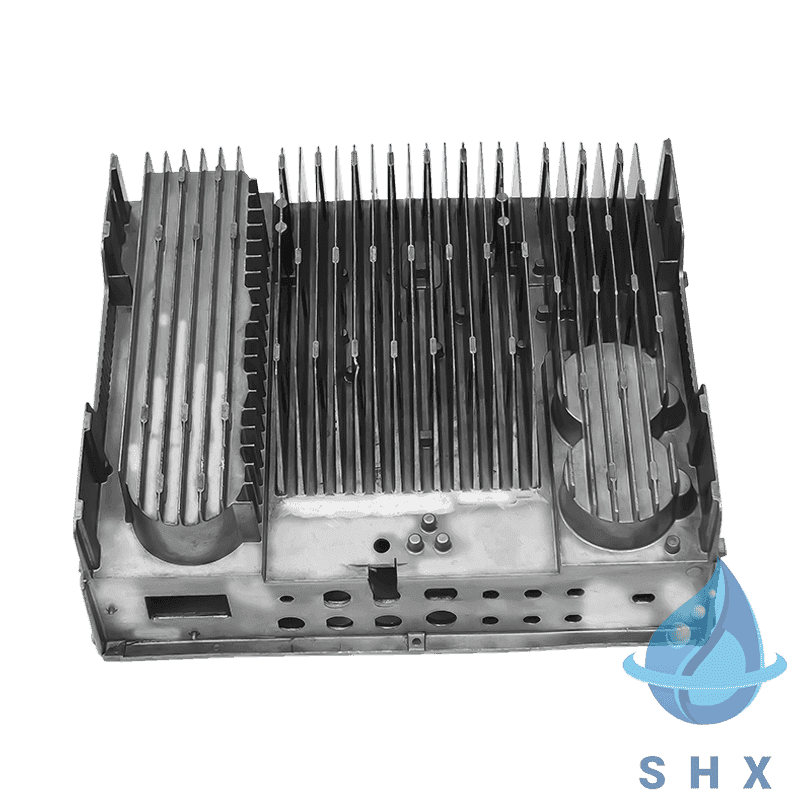

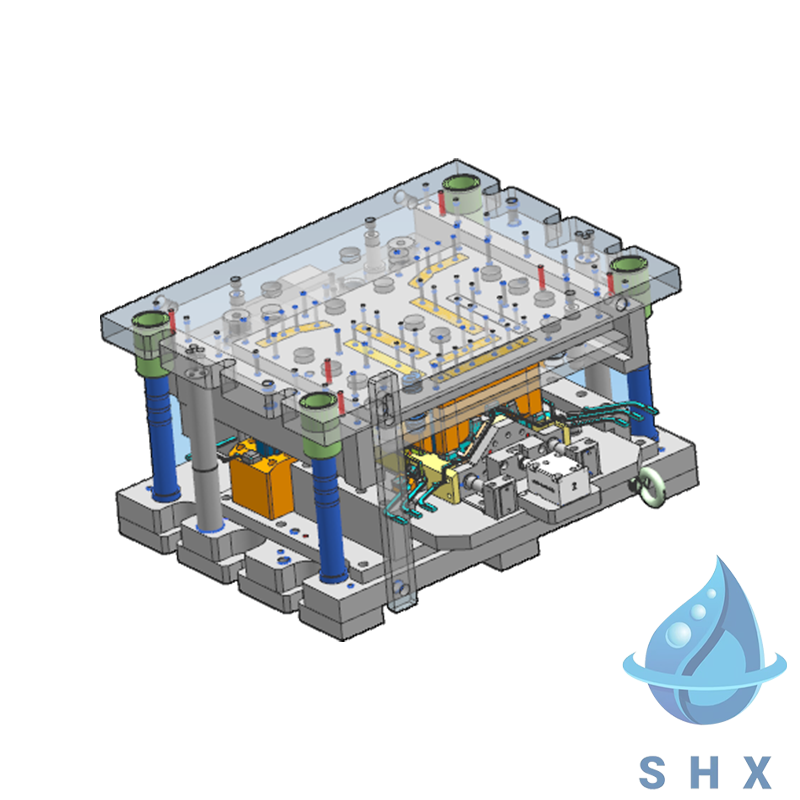

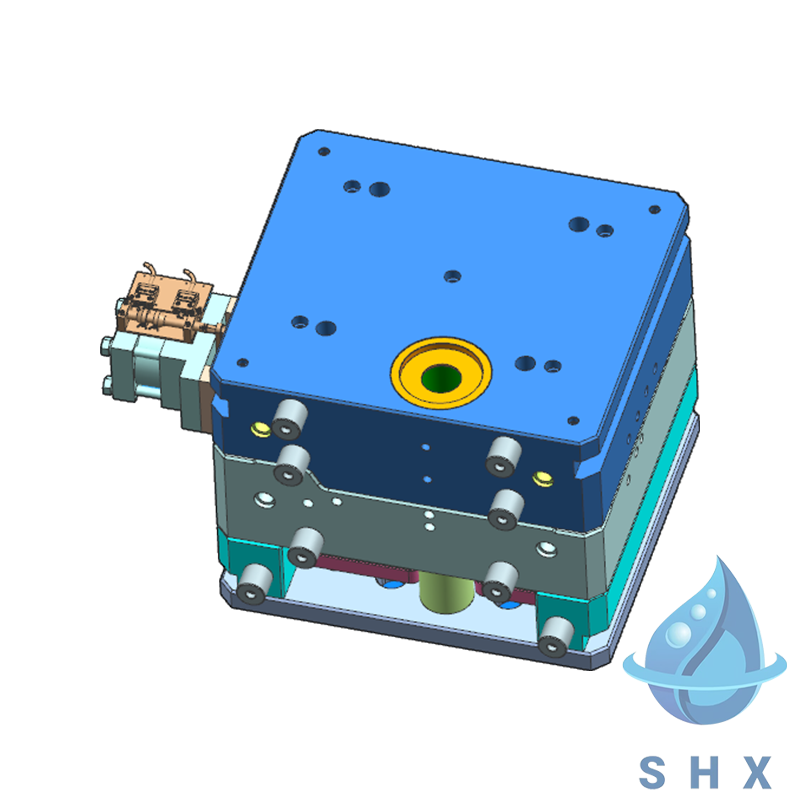

(2) Energy Storage Aluminum Die-castings

Aluminum die-castings also play a crucial role in energy storage equipment (such as outdoor energy storage power supplies, home energy storage systems, and industrial energy storage cabinets), primarily used for battery module housings, inverter housings, brackets, and power supply housings.

The core requirements of the energy storage industry for die-cast aluminum parts include:

Good heat dissipation performance: Energy storage equipment generates a large amount of heat during long-term operation. High-heat-dissipation aluminum die-cast housings can effectively improve system stability and reduce failures.

High strength and protection: Die-cast aluminum housings provide sufficient mechanical strength to protect internal batteries and electronic components from external impacts and vibrations.

Strong corrosion resistance: Aluminum alloys are naturally oxidation-resistant, suitable for complex environments such as outdoor, coastal, and humid environments.

Flexible structural customization: Internal wiring channels, mounting columns, heat dissipation fins, and other structures can be integrally formed, improving product compactness and reliability.

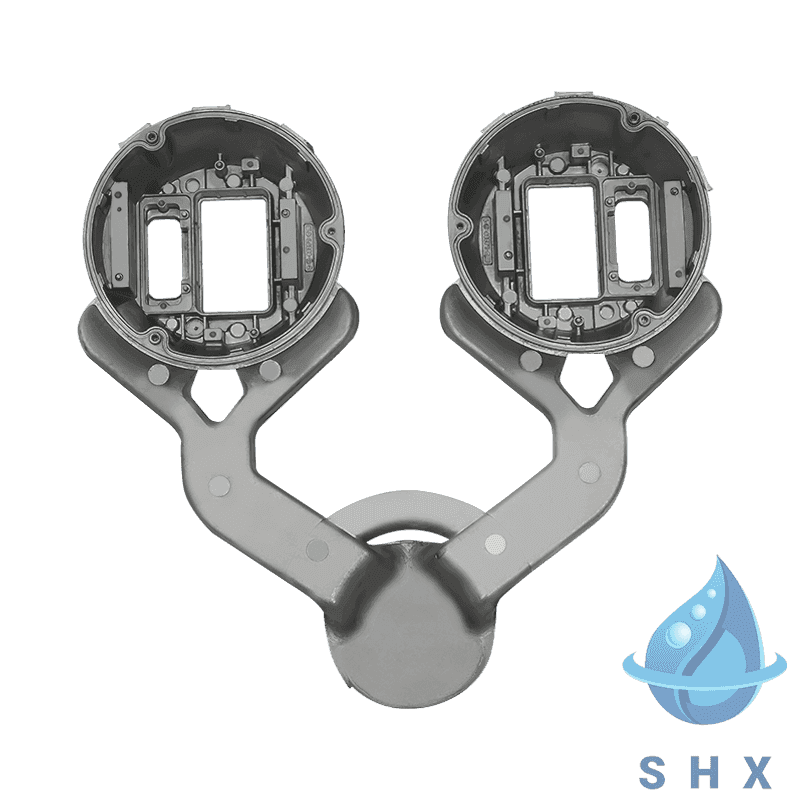

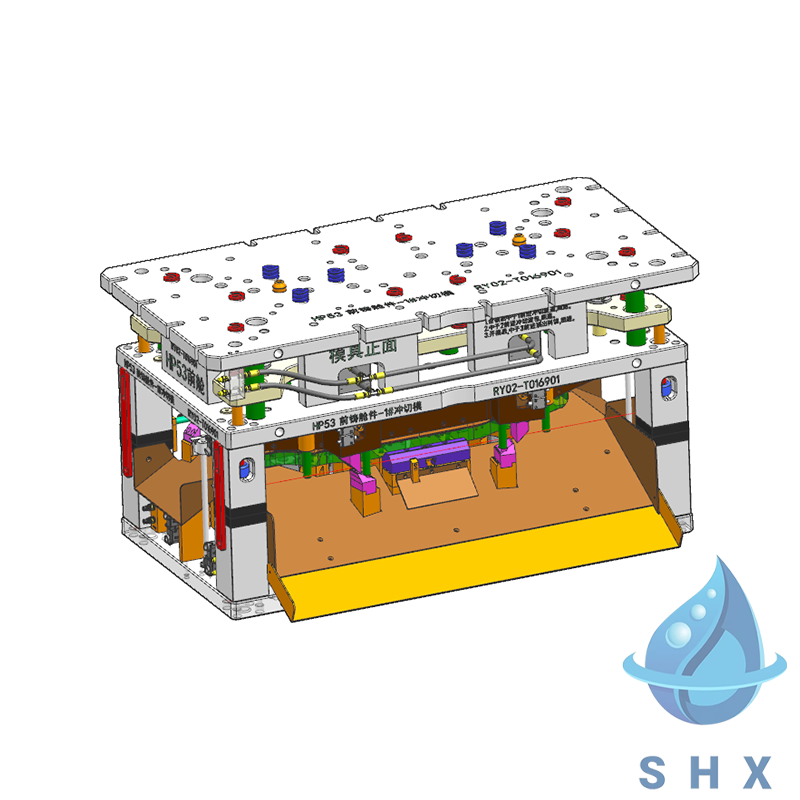

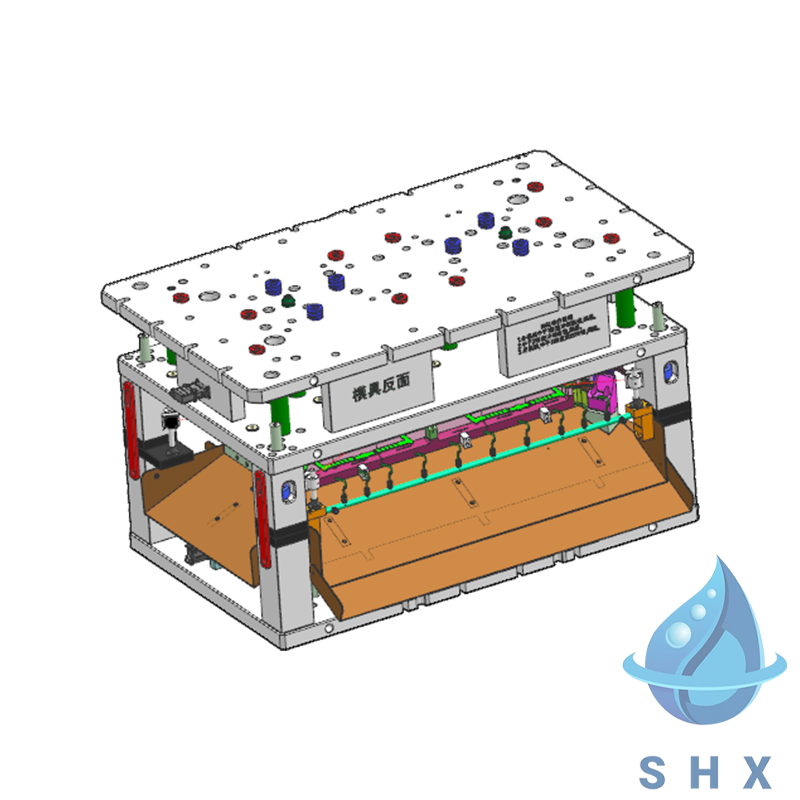

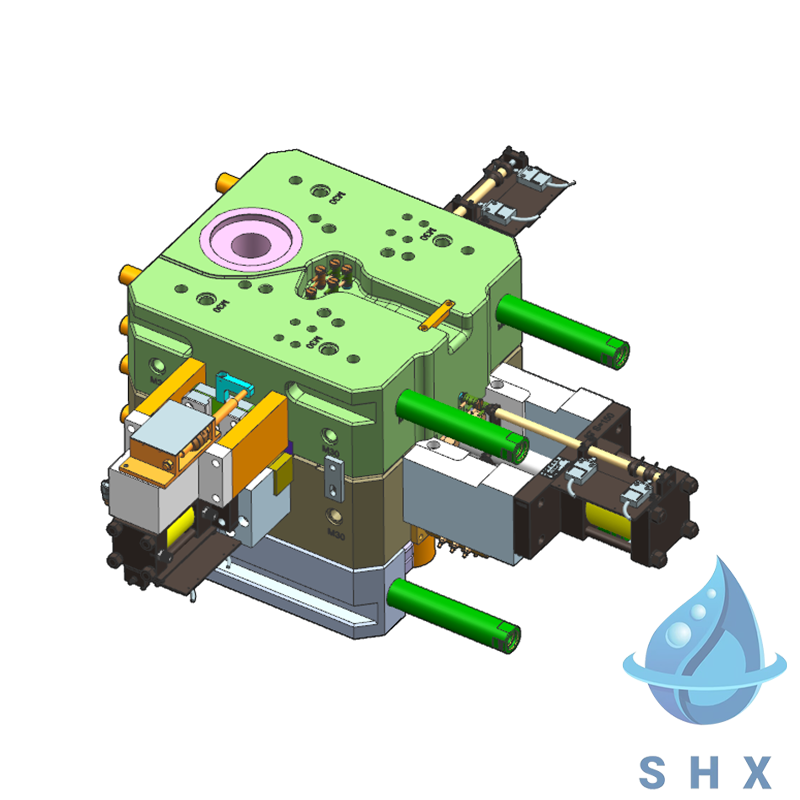

(3) Aluminum Die-Casting Parts for Cameras

Aluminum die-casting parts are widely used in SLR cameras, mirrorless cameras, action cameras, industrial cameras, and other equipment for camera body shells, lens structural components, bracket parts, and internal precision frames.

Their main advantages are:

Superior Rigidity and Stability: Ensures the stable positioning of precision structures such as lenses and sensors, reducing the impact of vibration on image quality.

Lightweight and Portable: Lighter than materials such as stainless steel, suitable for outdoor photography and handheld applications.

Strong Precision Forming Capability: Complex structures can be formed in one piece, improving assembly accuracy and enhancing the overall durability of the camera.

Excellent Surface Finishing Performance: Can be easily processed with sandblasting, oxidation, and wire drawing to achieve a high-end appearance.

Aluminum die-casting technology has become an important technological foundation for the manufacture of high-quality camera equipment.

2. Frequently Asked Questions about Aluminum Die Castings

Q1: What materials are used in aluminum die castings?

Commonly used materials include ADC12, A380, A360, AlSi10Mg, ADC6, etc. The selection is based on product strength, heat dissipation requirements and processing methods.

Q2: What is the difference between aluminum die-casting, aluminum extrusion and aluminum machining?

Die casting: suitable for complex structures, mass production, and high precision in one-time molding.

Extrusion: Suitable for long profiles with fixed cross-sections, such as heat sinks.

Machining: Suitable for small batches of parts with extremely high precision requirements.

Q3: What are the differences between aluminum die-casting parts for automobiles, energy storage and cameras?

Automobile: high strength, impact resistance, complex structure.

Energy storage: Prioritize heat dissipation performance and take protection into consideration.

Camera: lightweight, high-precision, and fine appearance processing.

Q4: Do aluminum die castings require post-processing?

Most require, such as: CNC finishing, deburring, surface spraying, anodizing, electroplating, etc., to ensure accuracy and apparent quality.

Q5: Are aluminum die castings environmentally friendly?

Aluminum is 100% recyclable and is a green and environmentally friendly material that is in line with the current trend of energy conservation and emission reduction.

Ningbo Shanghuaxin Machinery Co., Ltd. is a company with a specialization in the research, development, production and sales of aluminums alloy precision die-castings. The company's product range includes electronic components, automotive parts, medical equipment, communication equipment, lighting accessories and other precision industrial components.

English

English 中文简体

中文简体

0086-18158459905

0086-18158459905