1. What are energy storage aluminum die castings?

Energy storage aluminum die-casting parts are key structural components used in new energy storage systems. They are mostly used in battery module casings, battery trays, inverter casings, heat dissipation modules, mounting brackets, etc. Since energy storage equipment has been exposed to high power, high cycle and outdoor environmental conditions for a long time, it has very high requirements on the strength, heat dissipation, sealing and corrosion resistance of die castings, so aluminum die casting has become one of the main manufacturing processes.

2. Advantages of energy storage aluminum die castings

(1) Lightweight design

The low density of aluminum alloy can significantly reduce the weight of energy storage boxes and heat dissipation shells, making the entire energy storage system easier to transport and install. It also increases the energy density of a single unit to meet the lightweight needs of outdoor energy storage, large power stations and mobile energy storage equipment.

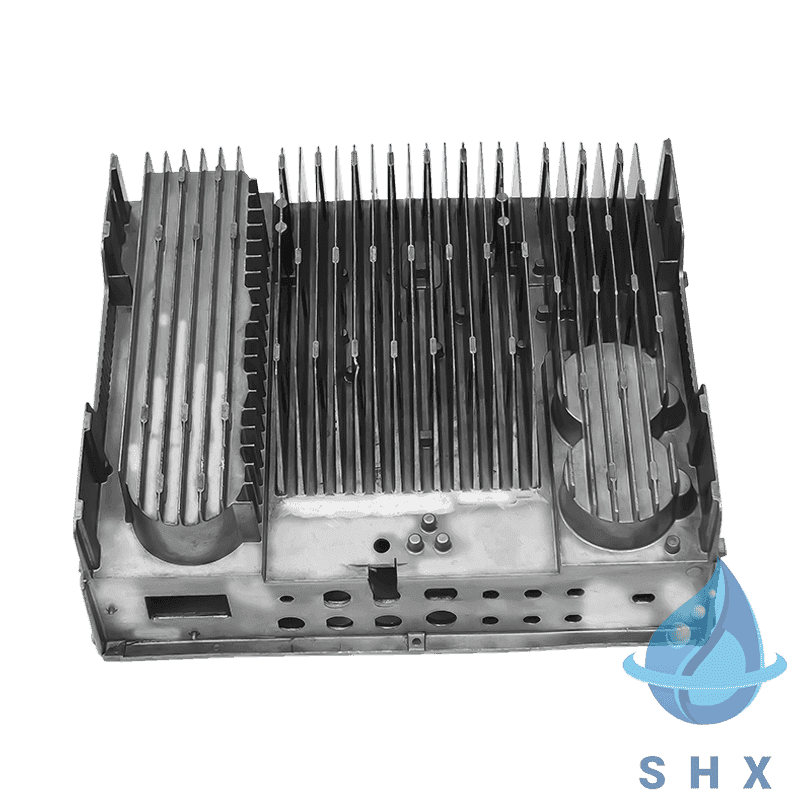

(2) Improve heat dissipation efficiency

The battery module of the energy storage system requires efficient heat dissipation to maintain stability. Aluminum die-casting parts have good thermal conductivity and can be designed into complex structures with heat sinks and ventilation slots to help reduce battery core temperature and extend the service life of the energy storage system.

(3) High structural strength

Die-cast aluminum parts have excellent pressure resistance, earthquake resistance and impact resistance, which can effectively protect battery modules and electronic systems. They are suitable for high-intensity application scenarios such as integrated optical storage machines, outdoor energy storage cabinets, and home energy storage systems.

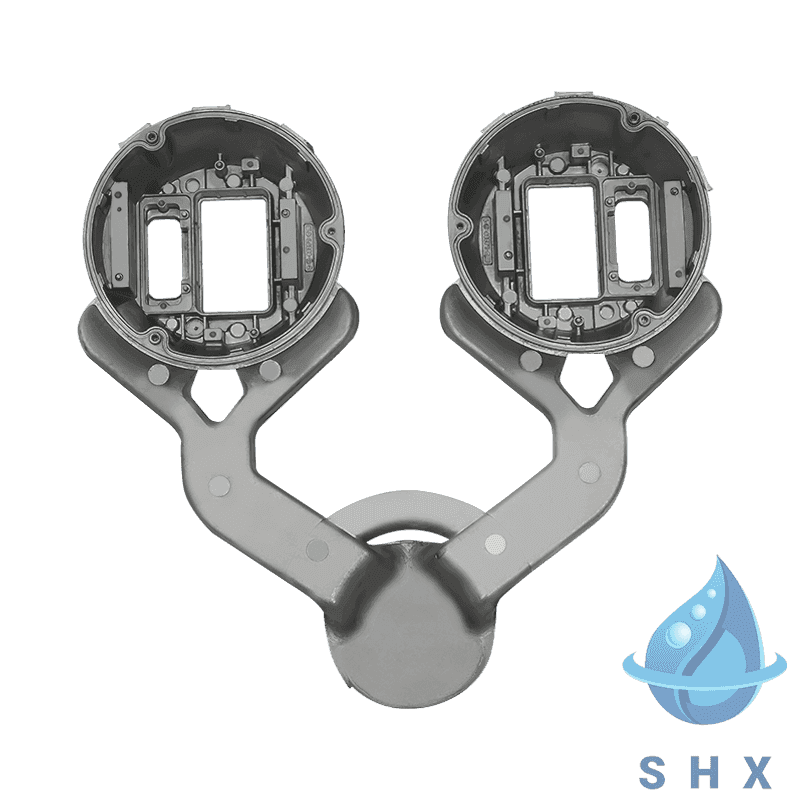

(4) One-piece molding reduces assembly links

The die-casting process can form complex structures, such as reinforcing ribs, mounting holes, wire channels, etc., in one go, reducing welding and riveting steps, improving product accuracy and stability, and reducing production and assembly costs.

(5) Strong corrosion resistance

Aluminum alloy has strong oxidation resistance, and the surface can be sprayed, anodized, electrophoresed and other treatments to improve salt spray, ultraviolet and humidity resistance, and is suitable for energy storage applications in different climate environments.

3. Common faults of automotive aluminum die castings

Automotive aluminum die-casting parts are widely used in engine systems, gearbox casings, chassis structural parts, electronic controller casings, cooling systems, etc. Due to their ability to withstand high temperatures, high pressures, vibrations and long-term mechanical loads, some typical faults often occur during their use, which need to be identified and dealt with in a timely manner. The most common failure is the problem of porosity inside the casting. Porosity is usually caused by air entrainment during the die casting process, uneven flow of molten metal, or poor mold venting. Porosity not only affects the appearance quality, but also reduces the density and overall strength of the material. In severe cases, it may cause cracks, leakage or reduced load-bearing capacity of the parts during use.

Another typical failure is cracks, including cold cracks, hot cracks, and fatigue cracks during use. Cracks are often related to factors such as uneven mold temperature, unreasonable injection speed, too low temperature of the molten metal or stress concentration. When aluminum die castings are subjected to vibration, alternating loads or thermal cycles for a long time, fatigue cracks may gradually develop, eventually leading to part breakage or failure. Cracks have a great impact on automobile safety, especially load-bearing structures such as chassis parts and engine casings, which must be prevented through design optimization, process improvement and material selection.

Common faults table of energy storage aluminum die castings:

| Fault type |

Possible reasons |

solution |

| Porosity/seal failure |

1. Gas residue in thin-walled sealing structure

2. Improper high vacuum die casting parameters (such as insufficient vacuum)

3. Uneven cooling leads to micropores |

1. Using high vacuum die casting (vacuum degree ≤ 50mbar)

2. Add a partial extrusion pin (Sealing Pin)

3. Helium leak detection + local impregnation treatment |

| Thermal deformation (high temperature conditions) |

1. Aluminum alloy has insufficient high-temperature strength (such as ADC12 temperature resistance <150℃)

2. Die castings have large wall thickness gradients

3. Thermal cycle stress concentration |

1. Switch to high heat-resistant alloys (such as AlSi10MgMn)

2. Optimize the design of heat dissipation ribs (uniform wall thickness)

3. T6 heat treatment improves creep resistance |

| Corrosion (electrolyte/environment) |

1. Micropores on the surface of die castings lead to pitting corrosion

2. The Fe content in the alloy exceeds the standard (>1.5%)

3. Surface treatment is not up to standard (such as anodized film thickness <10μm) |

1. Micro arc oxidation (MAO) or powder coating

2. Control Fe content and add Mn to neutralize

3. Passivation treatment (chromate or chromium-free passivation) |

| Structural cracking (vibration loads) |

1. Internal shrinkage of die castings (especially bolt connections)

2. The die-casting process window is narrow (such as mold temperature fluctuation ±20℃)

3. Insufficient fatigue strength |

1. Local extrusion strengthening + X-ray flaw detection

2. Use mold temperature machine control (±5℃)

3. Optimize the layout of stiffeners (to avoid stress concentration) |

4. Frequently Asked Questions about Energy Storage Aluminum Die Castings

Q1: Why do energy storage aluminum die-casting parts need to use the vacuum die-casting process?

Energy storage components usually require airtightness and high strength, such as battery cases and liquid cooling modules. Vacuum die-casting can effectively reduce pores, improve sealing and pressure resistance, and avoid problems such as leakage and cracks during use.

Q2: What aluminum alloy materials can be used for energy storage aluminum die castings?

Common materials include:

ADC12: Universal structural component

A380: high-strength shell

6061, 6063: Cooling modules and structural parts

AlSi10Mg: high-strength, lightweight parts (commonly used in energy storage trays and cold plates)

Material selection depends on thermal needs, strength requirements, and weight requirements.

Q3: What surface treatment is required for energy storage aluminum die castings?

Common treatments include:

Powder spraying: improve weather resistance

Anodizing: Enhances corrosion resistance

Electrophoresis: Enhanced adhesion and salt spray resistance

Sand blasting/shot blasting: improve surface uniformity

The process is determined based on whether the energy storage system is used outdoors or in a high-humidity environment.

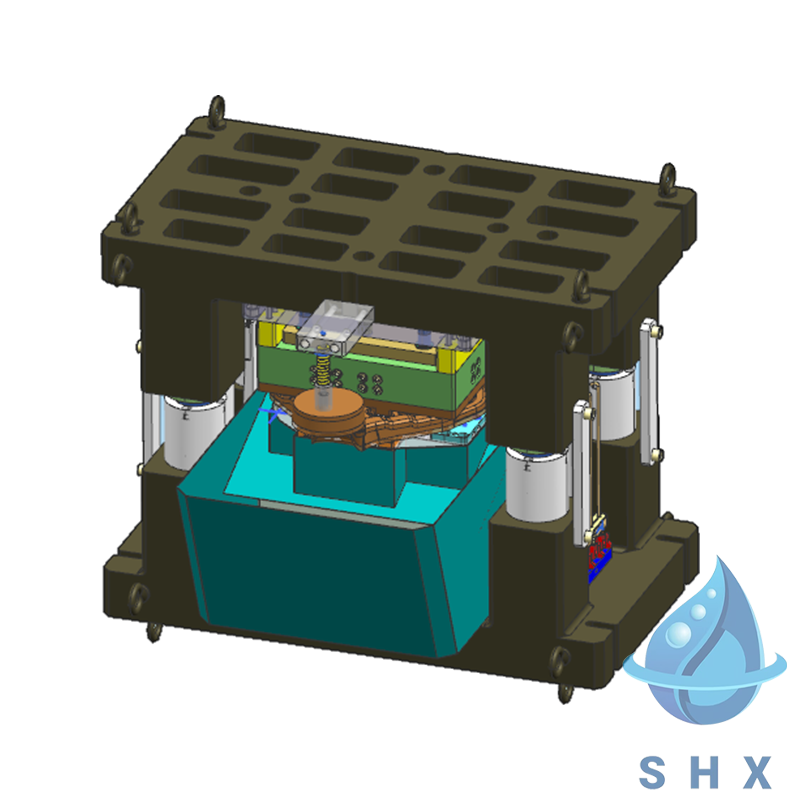

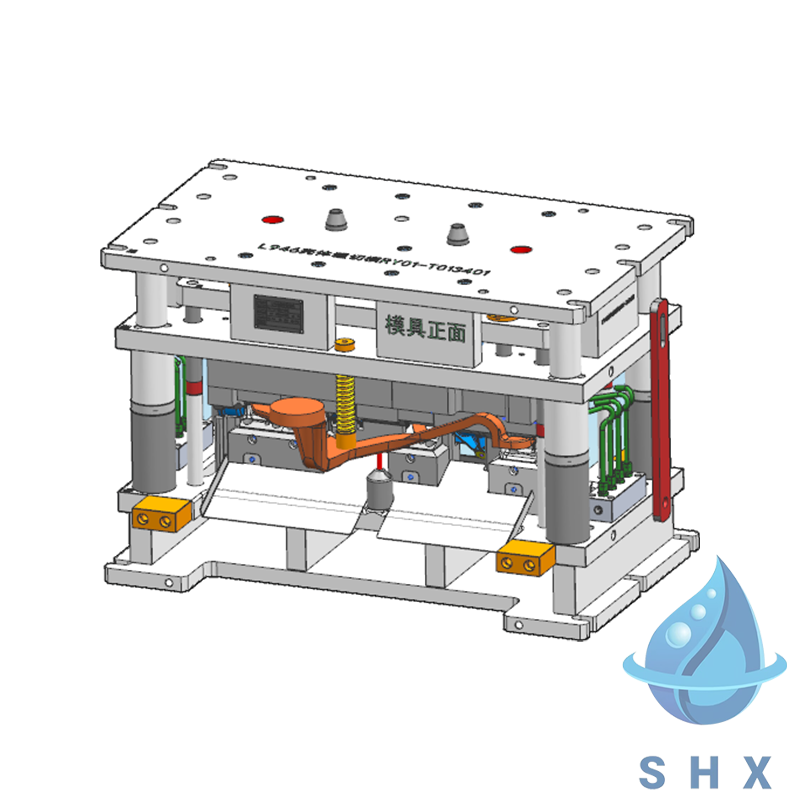

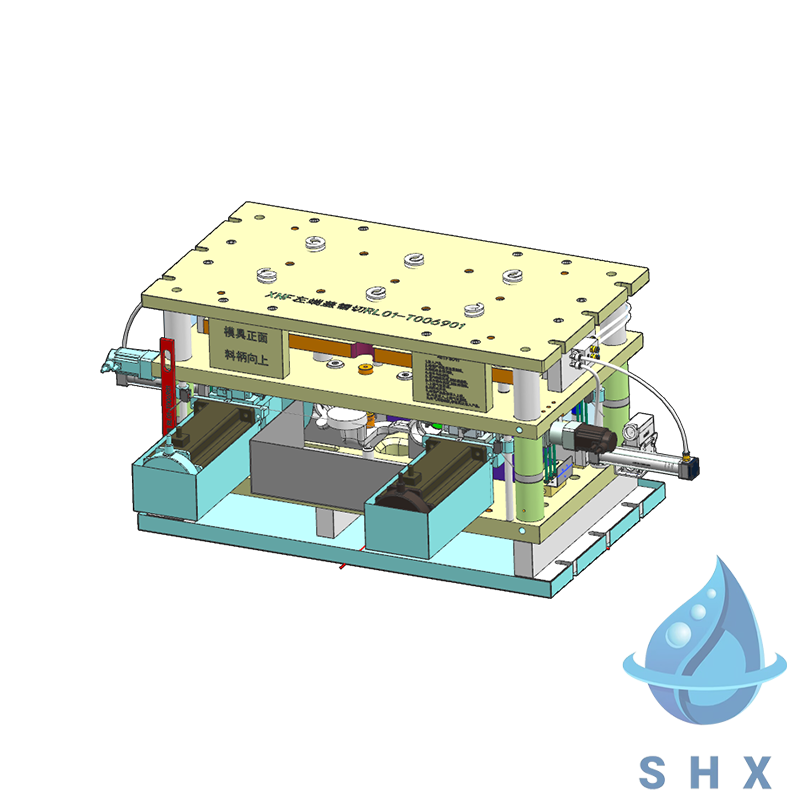

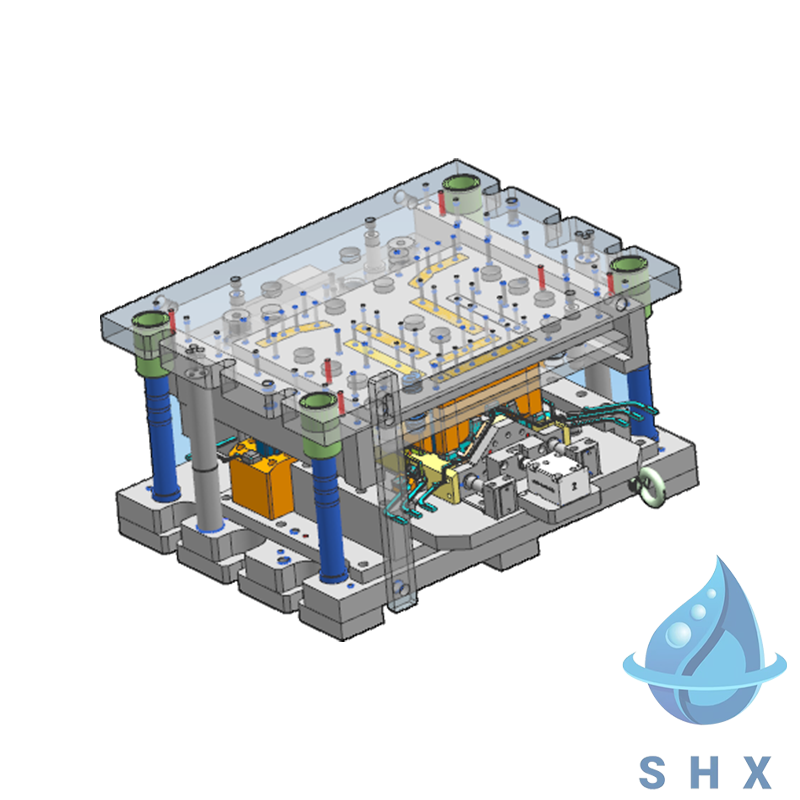

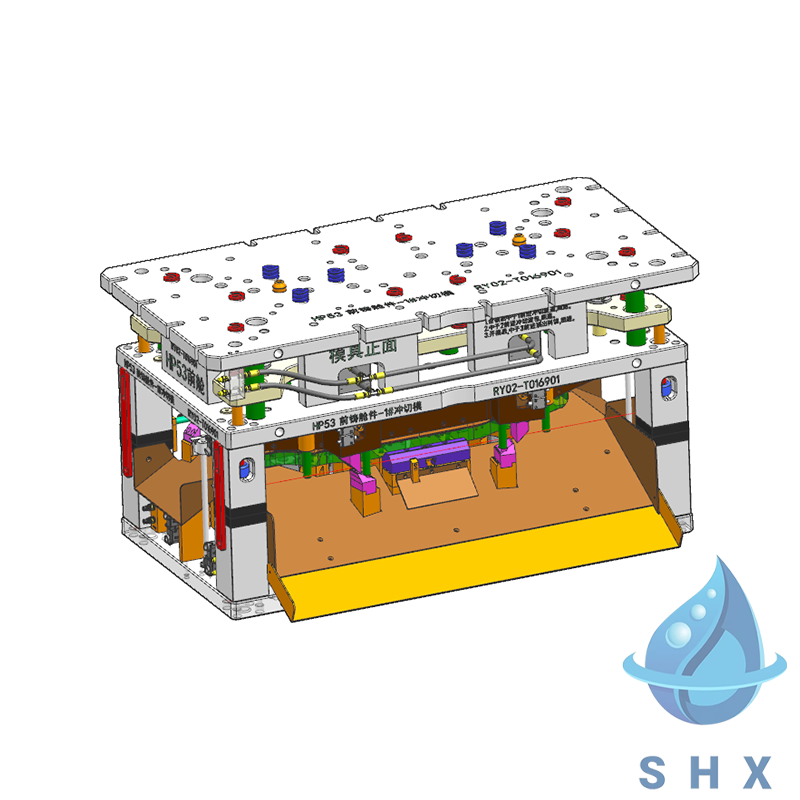

NINGBO SHANGHUAXIN MACHINERY CO., LTD. is a professional manufacturer of energy storage aluminum die castings.We provide die-casting molds for energy storage components like battery covers and radiators. These molds are crafted to ensure optimal thermal management and structural integrity, crucial for reliable energy storage applications. Designed for precision and durability, they enable the production of high-quality parts that perform consistently under demanding conditions.

English

English 中文简体

中文简体

0086-18158459905

0086-18158459905